Standing seam metal roofs are becoming increasingly popular due to their durability, efficiency, and sleek appearance. Understanding the specifications of these roofs is crucial for making informed decisions about your roofing project. This guide will provide a comprehensive overview of Standing Seam Metal Roof Specifications, including key features, materials, and installation considerations.

What is a Standing Seam Metal Roof?

A standing seam metal roof is characterized by its vertical seams that interlock, creating a continuous surface with no exposed fasteners. This design feature offers numerous benefits, including enhanced weather resistance and a clean, modern look.

Key Features

- Vertical Seams: The seams are raised above the level of the panel, creating a watertight barrier.

- Interlocking Panels: Panels are connected without visible fasteners, reducing the risk of leaks and improving the roof’s aesthetic appeal.

- Durable Materials: Typically made from high-quality metals like steel, aluminum, or copper, standing seam roofs are known for their longevity and resistance to various weather conditions.

Standing Seam Metal Roof Specifications

1. Materials

Metal Panels: The choice of metal significantly impacts the roof’s performance and appearance. Common materials include:

- Steel: Known for its strength and affordability, steel is often coated with zinc or a zinc-aluminum alloy to prevent rust.

- Aluminum: Lightweight and resistant to corrosion, aluminum is ideal for coastal areas with high salt exposure.

- Copper: Though more expensive, copper offers exceptional durability and develops a distinctive patina over time.

Coatings: Metal panels are usually coated with protective finishes to enhance their durability and aesthetic appeal. Common coatings include:

- Kynar 500®: A high-performance coating that offers excellent resistance to UV radiation and corrosion.

- Polyester: Provides good durability and color retention, though not as long-lasting as Kynar 500®.

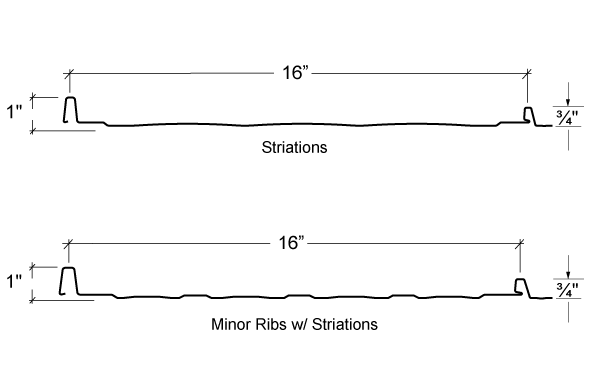

2. Panel Profiles

Seam Height: The height of the standing seam can vary, affecting the roof’s performance and appearance. Typical seam heights range from 1.5 inches to 2 inches.

Panel Width: Panels can come in various widths, usually between 12 to 20 inches. The width of the panel can influence both the roof’s aesthetic and its installation complexity.

Panel Length: Panels are available in custom lengths, reducing the need for seams and improving the roof’s water resistance. However, longer panels can be more challenging to handle and install.

3. Fastening Systems

Hidden Fasteners: Standing seam roofs use concealed fasteners, which are hidden beneath the seam. This design prevents water infiltration and enhances the roof’s appearance.

Clip Systems: Panels are typically secured using metal clips that allow for thermal expansion and contraction. These clips are fastened to the roof deck and support the panels.

4. Installation Considerations

Substrate Preparation: A solid and clean substrate is essential for proper installation. The roof deck should be smooth and free of debris to ensure a secure fit.

Thermal Expansion: Metal roofs expand and contract with temperature changes. Proper installation techniques, such as using clips and allowing for expansion, are crucial to accommodate these movements.

Weather Conditions: Installing a metal roof in extreme weather conditions can be challenging. Ideally, installation should be done in mild weather to avoid complications.

5. Performance and Durability

Weather Resistance: Standing seam metal roofs are highly resistant to severe weather conditions, including heavy rain, snow, and high winds. The raised seams and interlocking panels create a watertight barrier.

Longevity: With proper maintenance, standing seam metal roofs can last 50 years or more. Their durability and resistance to corrosion make them a long-term investment.

Energy Efficiency: Metal roofs reflect solar heat, which can reduce cooling costs. Many standing seam metal roofs are available with reflective coatings that enhance their energy efficiency.

Benefits of Standing Seam Metal Roofs

1. Aesthetic Appeal

Standing seam metal roofs offer a sleek, modern appearance that complements various architectural styles. The clean lines and smooth surface of the panels enhance the overall look of the building.

2. Low Maintenance

These roofs require minimal maintenance compared to other roofing materials. The lack of exposed fasteners and seams reduces the risk of leaks and other issues.

3. Environmental Benefits

Metal roofs are often made from recycled materials and are themselves recyclable at the end of their lifespan. Additionally, their energy efficiency contributes to reduced environmental impact.

Maintenance and Care

Regular Inspections

- Check for Damage: Regularly inspect the roof for any signs of damage or wear, such as dents or loose panels.

- Clean Debris: Remove leaves, branches, and other debris that can obstruct drainage or damage the roof.

Cleaning

- Use Mild Detergents: Clean the roof with mild detergents and water to remove stains and grime. Avoid harsh chemicals that can damage the coating.

- Avoid Pressure Washing: Pressure washing can strip the protective coating and cause damage. Use a soft brush or cloth instead.

Addressing Issues

- Repair Damage Promptly: Address any damage or issues as soon as they are identified to prevent further problems.

- Consult Professionals: For significant repairs or maintenance, consult with roofing professionals who have experience with standing seam metal roofs.

Conclusion

Understanding the specifications of standing seam metal roofs is essential for making an informed decision about your roofing needs. From material choices to installation considerations, each aspect plays a crucial role in the roof’s performance, durability, and appearance. By selecting the right materials and following proper installation and maintenance practices, you can enjoy the many benefits of a standing seam metal roof for years to come.

Leave a Reply