When it comes to building a metal roof, precision is key. The importance of a Metal Roof Detail Drawing cannot be overstated, as it serves as the blueprint for the successful installation of a durable and aesthetically pleasing metal roof. Whether you are a contractor, architect, or a homeowner planning a roofing project, understanding the intricacies of these drawings is crucial to ensure that your metal roof performs efficiently and lasts for decades.

This article covers Metal Roof Detail Drawings, their importance, key components, and tips for accurate creation or interpretation. If you’re looking to explore metal roofing design and installation, this guide is for you.

Read too: Hail Damage Roof Repair: Essential Guide to Restoring Your Home’s Protection

What is a Metal Roof Detail Drawing?

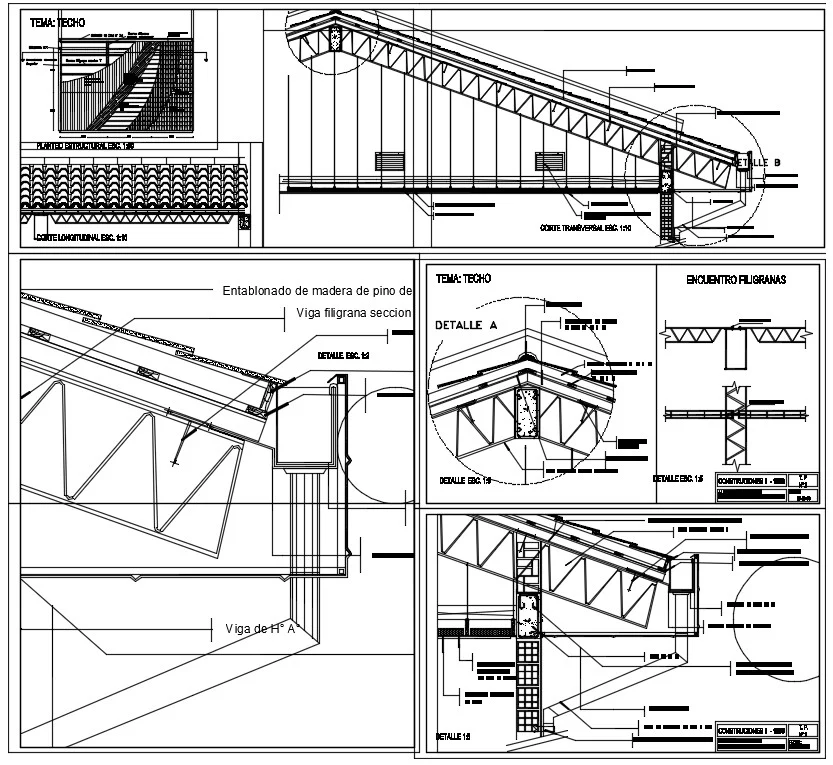

A Metal Roof Detail Drawing is a technical plan showing how to install a metal roof, including dimensions, materials, fastener placements, roof slope, flashing, and other key elements.

Architects and engineers use these drawings to communicate designs to builders, ensuring all components meet project specifications. They can range from basic overviews to detailed plans, showing cross-sections, material layers, and fastening methods.

Why is a Metal Roof Detail Drawing Important?

Accurate Metal Roof Detail Drawings are vital for several reasons:

- Precision in Installation: These drawings eliminate guesswork by providing exact specifications for every component of the roof. This ensures that installers know the correct placement of metal panels, fasteners, and flashing, which are critical for the roof’s durability and performance.

- Avoiding Structural Issues: Without a clear and detailed drawing, mistakes in installation can occur, leading to potential structural issues such as leaks, improper drainage, or even roof failure during extreme weather events. A detailed drawing helps to avoid these problems by ensuring the roof is installed according to design.

- Efficiency and Time Savings: A Metal Roof Detail Drawing can significantly speed up the installation process. With a clear plan to follow, contractors can work more efficiently, reducing the time spent on-site and minimizing errors that could result in costly rework.

- Code Compliance: Building codes and regulations often require detailed construction drawings to ensure that the installation meets safety standards. A proper metal roof drawing helps to ensure that the roof complies with local building codes and standards, avoiding potential legal issues down the line.

Key Components of a Metal Roof Detail Drawing

Understanding the components of a Metal Roof Detail Drawing is essential for anyone involved in the roofing process. These components typically include:

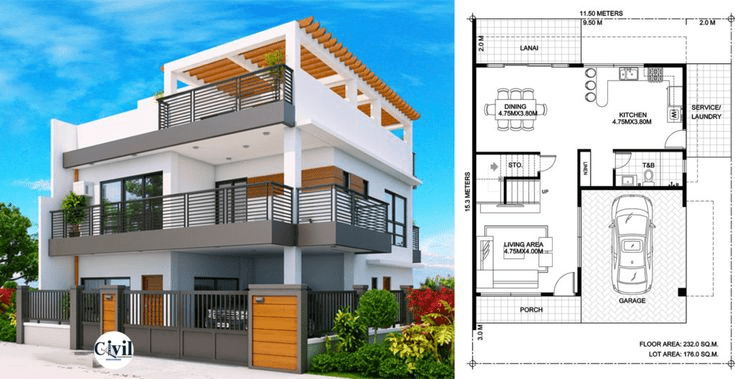

1. Roof Pitch and Slope

The roof pitch is the measure of the steepness of a roof and is one of the most critical factors in determining how water and snow will shed from the surface. A Metal Roof Detail Drawing will specify the pitch of the roof, which can vary based on design preferences and local weather conditions. It is typically expressed as a ratio (e.g., 4:12), indicating how many inches the roof rises for every 12 inches of horizontal run.

2. Metal Panel Layout

The layout of the metal panels is a fundamental part of the drawing. It shows how the metal sheets will be arranged across the roof’s surface, including panel sizes, orientation, and seam locations. This layout is crucial for determining the amount of material required and ensuring that the roof has the necessary structural integrity.

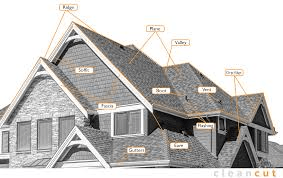

3. Flashing Details

Flashing is essential in preventing water from seeping into areas where different roof elements meet, such as chimneys, skylights, and vent pipes. A Metal Roof Detail Drawing includes comprehensive flashing details, showing how flashing should be installed around these vulnerable areas to prevent leaks.

4. Fastener Placement

The drawing will also specify the type and location of fasteners, which are critical for securing metal panels to the roof deck. Improper fastener placement can lead to roof failure, making this an essential component of the drawing. The detail drawing will typically include instructions on the number and spacing of fasteners, as well as the type of fasteners to use.

5. Roof Ventilation

Proper ventilation is crucial for maintaining the longevity of a metal roof. The Metal Roof Detail Drawing will often include the placement of ridge vents, soffit vents, or other ventilation systems that allow for the movement of air through the attic space. This helps to regulate temperature and prevent moisture buildup, which can lead to mold or structural damage.

6. Underlayment and Insulation

While the metal panels are the visible part of the roof, the underlayment and insulation beneath the panels are equally important. The Metal Roof Detail Drawing will specify the type and thickness of the underlayment (usually a waterproof material) as well as any insulation that needs to be installed for energy efficiency and noise reduction.

7. Edge Details

The edges of a metal roof, including eaves and rakes, need to be properly sealed to prevent water infiltration. A Metal Roof Detail Drawing will provide instructions for the installation of drip edges and other edge treatments that protect the roof from water damage and provide a finished appearance.

How to Create or Interpret a Metal Roof Detail Drawing

Whether you are an architect creating a metal roof drawing or a contractor interpreting one, there are some key principles to keep in mind:

1. Accuracy is Key

Creating a Metal Roof Detail Drawing requires precise measurements and attention to detail. Every aspect of the roof, from the slope to the size of the metal panels, needs to be accurate to ensure a successful installation. Make sure to double-check all measurements before finalizing the drawing.

2. Use Standard Symbols and Notations

When creating a metal roof drawing, it’s essential to use standard symbols and notations that are universally recognized in the construction industry. This ensures that contractors and builders can easily understand the plan and follow it correctly.

3. Include Cross-Sections

Cross-sectional views are an integral part of a Metal Roof Detail Drawing. These views provide a clearer picture of how the roof system is layered, from the roof deck to the metal panels. Cross-sections help to clarify details that might be difficult to see in a top-down view, such as underlayment installation or flashing placement.

4. Specify Materials

The drawing should clearly indicate the materials to be used for each part of the roof. This includes the type of metal (e.g., galvanized steel, aluminum, copper), the thickness of the panels, the type of underlayment, and the fasteners. Specifying the materials helps contractors source the right products and ensures that the roof meets design and performance expectations.

5. Review and Collaborate

Before finalizing the Metal Roof Detail Drawing, collaborate with professionals like structural engineers or roofing specialists. This helps address potential issues and ensures the drawing meets safety and performance standards.

Common Mistakes to Avoid in Metal Roof Detail Drawings

Even with detailed drawings, mistakes can happen. Here are some common errors to avoid when creating or interpreting a Metal Roof Detail Drawing:

1. Overlooking Ventilation Needs

One of the most common mistakes is neglecting proper roof ventilation. Poor ventilation can lead to moisture buildup, which can cause mold growth or structural damage. Make sure the drawing includes adequate ventilation features, such as ridge vents or soffit vents.

2. Improper Fastener Placement

Incorrect fastener placement can lead to roof leaks or panel blow-offs in high winds. Ensure that the drawing provides detailed instructions on the placement and type of fasteners to be used. Fasteners should be placed according to manufacturer recommendations and the building code.

3. Neglecting Flashing

Flashing is a critical component for preventing water infiltration around roof penetrations, valleys, and edges. A Metal Roof Detail Drawing should clearly indicate the placement and type of flashing required for each part of the roof. Neglecting flashing can lead to leaks and water damage.

4. Inaccurate Slope Calculations

The slope of the roof is essential for ensuring proper water drainage. If the slope is too shallow, water can pool on the surface, leading to corrosion or leaks. Make sure the drawing specifies the correct slope based on the local climate and roof design.

Conclusion

A Metal Roof Detail Drawing is an essential tool in ensuring the successful installation of a metal roofing system. It provides precise instructions for contractors, reducing the likelihood of errors and ensuring that the roof performs as expected. Whether you are designing a new metal roof or overseeing the installation process, understanding the components of a metal roof drawing is key to achieving a durable, long-lasting, and aesthetically pleasing result.

Careful planning, attention to detail, and professional collaboration ensure a metal roof provides long-lasting protection and beauty. From the initial design phase to the final inspection, the importance of a detailed and accurate drawing cannot be overstated.

Leave a Reply