Installing a metal roof is one of the most durable and long-lasting options for homeowners, but one critical aspect of the installation process is often overlooked—proper metal roofing screw placement. Placing screws correctly is essential to ensuring your metal roof remains leak-free, secure, and able to withstand the elements for decades. In this article, we’ll explore everything you need to know about metal roofing screw placement, including the best practices, common mistakes to avoid, and why precise screw placement can make or break the longevity of your roof.

Understanding Metal Roofing Screw Placement for Maximum Durability

Correct screw placement on a metal roof is crucial for both its structural integrity and its ability to keep water out. Even small mistakes can lead to leaks, reduced durability, and potentially costly repairs down the road. Here’s what you need to know about the key aspects of proper metal roofing screw placement.

1. Why Screw Placement Matters

Metal roofing screws serve two important purposes: they attach the metal panels to the structure of the roof and create a watertight seal that prevents water from entering the building. Incorrectly placed screws can weaken the attachment of the metal panels, leaving your roof vulnerable to strong winds or other external forces. Even worse, if screws are over-tightened or placed incorrectly, they can damage the metal panels or fail to form a proper seal, leading to leaks.

This makes correct screw placement not just a matter of ensuring your roof stays in place but also crucial for protecting the structure beneath from moisture damage.

Read too: Hail Damage Roof Repair: Essential Guide to Restoring Your Home’s Protection

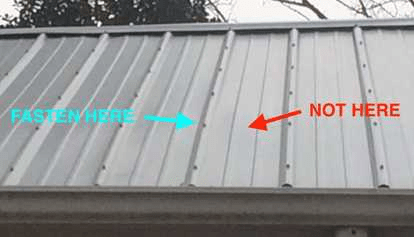

2. Screw Placement on the Flat vs. the Rib of the Panel

One of the most debated topics in metal roofing installation is whether screws should be placed on the flat part of the panel or the rib. Here’s what you need to know:

- On the Flat: Most experts recommend placing screws on the flat part of the panel. This method creates a tighter and more secure connection with the roof structure underneath. It also reduces the risk of screws backing out over time due to thermal expansion and contraction of the metal.

- On the Rib: Some installers place screws on the ribs, especially in older installations or certain styles of roofing. While this method can sometimes provide more flexibility, it is generally less secure than placing screws on the flat because it doesn’t create as strong of a connection with the decking or purlins underneath.

When possible, always place screws on the flat area of the panel for maximum stability and to avoid water pooling around the screw heads, which can increase the risk of leaks.

3. Correct Screw Depth

One of the most common mistakes in metal roofing screw placement is not screwing them in to the correct depth. If screws are over-tightened, they can warp the rubber washers that are designed to form a watertight seal between the screw head and the metal panel. Over time, this can cause the washer to crack and allow water to seep into the roof.

On the other hand, screws that are too loose won’t create a secure enough attachment, and they can easily back out over time, especially when the metal expands and contracts with changes in temperature. It’s essential to make sure screws are snug but not overly tightened. This ensures the washer creates a proper seal without being compromised.

4. Spacing and Alignment

The spacing and alignment of screws play a critical role in ensuring your metal roof performs well over time. Proper screw spacing varies depending on the specific type of metal roofing panel and the manufacturer’s recommendations, but in general, screws should be spaced about 12 to 18 inches apart horizontally, and every 24 to 30 inches vertically along the purlins or roof decking.

Ensuring that screws are evenly spaced and aligned will prevent issues such as:

- Uneven pressure distribution across the metal panels.

- Panels becoming loose or unstable over time.

- Aesthetic issues from uneven or crooked screws.

Always refer to the manufacturer’s installation guide for specific recommendations on screw spacing, as different panels and roof designs may require adjustments.

5. Using the Right Type of Screws

Not all screws are created equal, especially when it comes to metal roofing. The screws you use must be designed specifically for metal roofs, with features such as:

- Galvanized or Stainless Steel: These materials resist corrosion, which is crucial in preventing rust that can weaken the screws and compromise the roof’s integrity.

- Neoprene or EPDM Rubber Washers: These washers create a waterproof seal between the screw and the metal panel, ensuring no moisture gets in through the screw hole.

Using the correct screws, combined with proper metal roofing screw placement, will help ensure your roof remains leak-free and secure for many years.

Common Mistakes to Avoid in Metal Roofing Screw Placement

Even seasoned DIYers or inexperienced contractors can make mistakes during the installation process. Here are some common errors and how to avoid them:

1. Over-Tightening or Under-Tightening Screws

As mentioned earlier, finding the correct balance when tightening screws is critical. Over-tightening causes the washer to flatten out too much, leading to leaks, while under-tightening can cause screws to loosen over time. A good rule of thumb is to ensure that the washer is snug against the metal but not distorted.

2. Misaligned Screws

When screws aren’t placed in straight lines or consistent rows, not only does it create an unsightly appearance, but it also compromises the roof’s strength. Misalignment can result in uneven pressure distribution, which can eventually lead to loose panels or leaks. Using a chalk line as a guide during installation can help keep screws straight and evenly spaced.

3. Not Replacing Worn-Out Screws and Washers

Over time, even the best-placed screws may wear out, especially if the washers become cracked or corroded. It’s essential to conduct regular inspections of your metal roof and replace any screws or washers that show signs of wear. Failure to do so can lead to leaks and reduce the lifespan of your roof.

Best Practices for Metal Roofing Screw Placement

When it comes to metal roofing screw placement, following best practices can make a huge difference in the performance and durability of your roof. Here are some tips to ensure your installation is top-notch:

1. Start from the Eaves and Work Your Way Up

When installing screws, it’s best to start from the bottom of the roof (the eaves) and work your way upward toward the ridge. This ensures that panels overlap correctly and that screws are placed in a consistent pattern. Working upward also helps prevent issues with water drainage, as panels are designed to overlap in such a way that water naturally runs down and off the roof.

2. Use the Correct Tools

Using the right tools for the job is essential. A screw gun with adjustable torque settings is ideal for controlling how tightly the screws are fastened. This helps prevent over-tightening or under-tightening, both of which can lead to leaks or loose screws over time.

Additionally, it’s important to use the correct size bit for your screws to avoid stripping the screw heads, which can make future maintenance or replacement difficult.

3. Don’t Forget to Seal Around Penetrations

Any time you have a penetration through the metal roofing, such as for chimneys, vents, or skylights, it’s critical to ensure proper sealing. Use high-quality sealants and flashing around penetrations to prevent water from entering these vulnerable areas. Additionally, screws placed near penetrations should be double-checked for proper placement and sealing to avoid future leaks.

4. Conduct Regular Maintenance

A metal roof is a long-term investment, and like any major component of your home, it requires regular maintenance to ensure it performs well over its lifetime. Conduct annual roof inspections to check for loose screws, worn-out washers, or panels that have shifted due to wind or thermal expansion. Replacing screws and washers as needed will help keep your roof in excellent condition and prevent leaks before they start.

Conclusion

Metal roofing is a highly durable, energy-efficient, and low-maintenance option for homeowners, but the key to ensuring its longevity lies in proper installation—especially when it comes to metal roofing screw placement. Correctly placed screws will help keep your roof secure, prevent leaks, and withstand the rigors of wind, rain, and changing temperatures. By following best practices, avoiding common mistakes, and conducting regular maintenance, you can maximize the life of your metal roof and protect your home for decades to come.

Whether you’re installing a metal roof yourself or hiring a contractor, understanding the importance of proper metal roofing screw placement will ensure a durable, leak-free roof that stands the test of time.

Leave a Reply