Discover the key to ensuring your metal roof’s longevity and durability with optimal screw placement. Learn best placement for screws in metal roofing to maximize security and weather resistance.

Understanding the Importance of Screw Placement

Proper screw placement in metal roofing is critical for several reasons, including:

- Weatherproofing: Correct placement prevents water infiltration and potential leaks.

- Structural Integrity: Secure attachment enhances the roof’s ability to withstand wind and other environmental factors.

- Aesthetic Considerations: Well-placed screws maintain the roof’s sleek appearance.

Factors Affecting Screw Placement

Factors influencing best placement for screws in metal roofing include:

- Roof Pitch: Steeper pitches may require different spacing and placement techniques.

- Metal Type: Different metals (e.g., aluminum, steel) and roofing profiles (standing seam, corrugated) affect screw placement.

- Local Climate: Consider wind loads, snow accumulation, and temperature fluctuations.

Step-by-Step Guide to Optimal Screw Placement

Step 1: Choosing the Right Screws

Select screws designed for metal roofing, typically self-tapping and corrosion-resistant. Ensure they match your roof’s material and gauge.

Step 2: Determining Spacing and Layout

Follow manufacturer guidelines for screw spacing. Typically, screws are placed at panel overlaps and near roof edges.

Step 3: Preparing the Roof Surface

Clean and prepare the roof surface before installation to ensure proper adhesion and longevity.

Step 4: Placing Screws Correctly

Drive screws perpendicular to the roof surface to avoid stress points. Use a screw gun or drill with adjustable torque settings to prevent over-tightening.

Step 5: Sealing and Finishing

Apply sealant around each screw head to create a watertight seal. Check manufacturer recommendations for compatible sealants.

Common Mistakes in Screw Placement

Avoid these pitfalls when determining best placement for screws in metal roofing:

- Improper Spacing: Too few screws compromise structural integrity; too many may cause distortion.

- Incorrect Depth: Over-driving screws can damage panels; under-driving leaves gaps.

- Neglecting Sealant: Skipping sealant application increases the risk of leaks over time.

Read too: Is It Reasonable to Ask the Seller to Replace the Roof?

Maintenance Tips for Screwed Metal Roofing

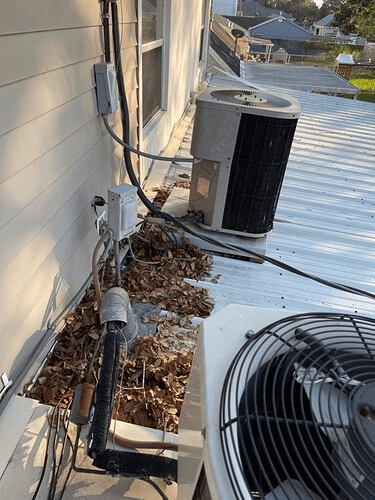

To extend your roof’s lifespan, implement these maintenance practices:

- Regularly inspect and tighten loose screws.

- Replace damaged screws promptly to prevent corrosion.

- Clear debris and inspect sealant annually.

Conclusion

Mastering best placement for screws in metal roofing ensures your roof remains secure and weather-resistant for years to come. Follow these guidelines to achieve optimal installation and maintenance practices.

Leave a Reply