When it comes to installing metal roofing, one common question that arises is, “Can you overlap metal roofing lengthwise?” Understanding the best practices for overlapping metal roofing is crucial for ensuring a durable and watertight installation. In this guide, we’ll delve into the details of lengthwise overlaps, their benefits, potential pitfalls, and best practices to help you achieve a professional and long-lasting metal roof.

What is Metal Roofing?

Overview of Metal Roofing

Metal roofing is a popular choice for both residential and commercial buildings due to its durability, longevity, and aesthetic appeal. It comes in various materials, including:

- Steel: Known for its strength and affordability.

- Aluminum: Lightweight and resistant to corrosion.

- Copper: Offers a distinctive appearance and longevity.

Read too: How To Replace A Mobile Home Roof: Step-by-Step Guide for Homeowners

Types of Metal Roofing Panels

- Standing Seam: Features interlocking vertical panels.

- Corrugated Metal: Known for its wavy pattern and ease of installation.

- Metal Shingles: Designed to mimic traditional roofing materials.

Why Overlap Metal Roofing?

Benefits of Overlapping

Overlapping metal roofing panels is a standard practice to ensure a watertight seal and enhance the roof’s durability. Overlapping provides several advantages:

- Preventing Leaks: Properly overlapping panels helps prevent water from seeping through seams.

- Enhancing Longevity: Reduces the risk of water damage and extends the life of the roofing material.

- Aesthetic Consistency: Ensures a uniform appearance and minimizes visible seams.

Types of Overlaps in Metal Roofing

- End-to-End Overlap: Involves overlapping the ends of metal panels to create a continuous surface.

- Side-to-Side Overlap: Ensures that adjacent panels overlap horizontally to prevent water infiltration.

Can You Overlap Metal Roofing Lengthwise?

Understanding Lengthwise Overlap

Lengthwise overlap refers to overlapping metal roofing panels along their length rather than across their width. This practice is less common but may be necessary in certain situations.

Factors to Consider for Lengthwise Overlap

- Panel Design and Type: The type of metal roofing panels you use will influence whether lengthwise overlaps are feasible. Panels with interlocking seams are generally more suitable for this type of overlap.

- Manufacturer’s Recommendations: Always refer to the manufacturer’s guidelines for specific instructions regarding lengthwise overlaps.

- Roof Slope and Pitch: The slope of your roof can affect how well lengthwise overlaps perform. Steeper slopes typically handle water better.

Pros and Cons of Lengthwise Overlap

Pros

- Increased Coverage: Lengthwise overlaps can be beneficial for roofs with unusual dimensions or configurations.

- Fewer Seams: Reduces the number of seams that need to be sealed, potentially decreasing the risk of leaks.

Cons

- Installation Complexity: Lengthwise overlaps can be more challenging to install compared to traditional side-to-side overlaps.

- Potential for Water Pooling: If not done correctly, lengthwise overlaps may lead to water pooling and leaks.

Best Practices for Overlapping Metal Roofing

Preparation and Planning

- Measure Accurately: Ensure precise measurements of your roof to determine the appropriate overlap.

- Check for Damage: Inspect existing panels for any signs of damage or wear before installing new ones.

- Consult Manufacturer Guidelines: Follow the specific recommendations for your chosen metal roofing panels.

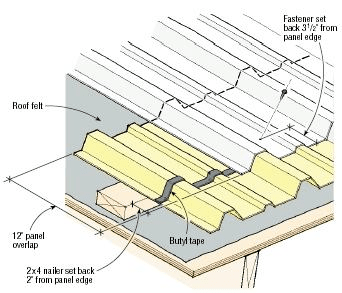

Installation Steps

- Align Panels Correctly: Ensure that panels are properly aligned before securing them.

- Secure Overlaps: Use appropriate fasteners and sealing methods to secure the overlaps and prevent water infiltration.

- Check for Proper Sealing: Verify that all overlaps are sealed correctly to ensure a watertight installation.

Common Issues and Solutions

- Improper Overlap: Ensure that overlaps are sufficient and correctly aligned to avoid leaks.

- Inadequate Sealing: Use high-quality sealants and follow manufacturer’s recommendations for sealing overlaps.

Conclusion

In summary, while overlapping metal roofing lengthwise is possible, it is less common than traditional side-to-side overlaps. Understanding the benefits and potential challenges of lengthwise overlaps will help you make informed decisions for your roofing project. By following best practices and consulting with professionals, you can ensure a durable and effective metal roofing installation.

Leave a Reply