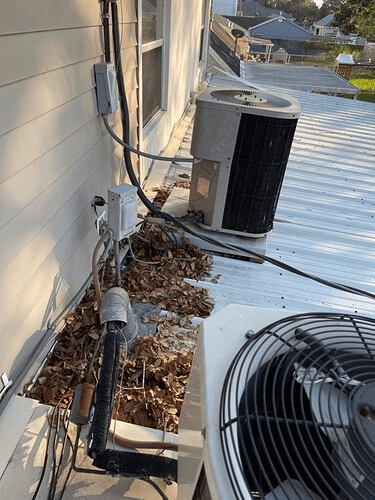

When it comes to installing a metal roof, proper furring strip spacing is a critical factor that directly impacts the roof’s performance and longevity. Furring strips are wooden or metal spacers placed horizontally over the roof’s deck to provide an even surface for the metal roofing panels to be attached. The spacing between these furring strips plays a significant role in ensuring the structural integrity and stability of the metal roof. In this article, we will delve into the importance of furring strip spacing for a metal roof, discuss the factors that influence the spacing, and highlight best practices to achieve a successful metal roofing installation.

Understanding the Significance of Furring Strip Spacing

The furring strip spacing serves as the foundation for the metal roof installation and affects various aspects of the roofing system.

- Structural Support: Properly spaced furring strips provide robust structural support for the metal roofing panels. The spacing ensures that the weight of the roof is evenly distributed, preventing sagging and potential structural damage.

- Ventilation: Furring strip spacing also facilitates proper attic ventilation. Adequate spacing allows air to flow freely beneath the metal roof, reducing heat buildup and preventing moisture-related issues, such as mold and rot.

- Thermal Expansion: Metal roofing materials expand and contract with temperature changes. The correct furring strip spacing allows for this thermal movement without causing stress or damage to the roofing system.

Factors Influencing Furring Strip Spacing

Consider various factors during metal roof installation to determine the ideal furring strip spacing.

- Roof Pitch: The slope or pitch of the roof plays a significant role in determining furring strip spacing. Steeper roof pitches may require closer spacing to provide adequate support, while lower pitches can accommodate wider spacing.

- Metal Roofing Material: Different types of metal roofing materials have varying weight and thermal expansion properties. Heavier materials or those with higher expansion rates may require closer furring strip spacing for proper support and movement allowance.

- Local Climate: The climate of the installation location is crucial in determining furring strip spacing. Areas with extreme temperature fluctuations may need wider spacing to accommodate metal expansion and contraction.

Best Practices for Furring Strip Spacing

To achieve an effective and long-lasting metal roof installation, it is essential to adhere to best practices for furring strip spacing.

- Manufacturer’s Recommendations: Always follow the manufacturer’s guidelines for furring strip spacing. Manufacturers conduct extensive testing to determine the optimal spacing for their specific metal roofing products.

- Roof Deck Inspection: Before installing furring strips, thoroughly inspect the roof deck for any damage, rot, or structural issues. Address any problems before proceeding with the installation.

- Ventilation Consideration: Ensure that the furring strip spacing allows for proper attic ventilation. Proper ventilation helps regulate temperature and prevents moisture buildup in the attic space.

Conclusion

Furring strip spacing is a crucial aspect of metal roof installation that should not be overlooked. Proper spacing provides essential structural support, facilitates ventilation, and allows for thermal expansion and contraction of the metal roofing materials. Follow the manufacturer’s spacing recommendations for furring strips when installing a metal roof. Consider factors like roof pitch, roofing material, and local climate. Adhering to best practices ensures a stable, durable, and efficient metal roofing system that protects your home for years.

Leave a Reply