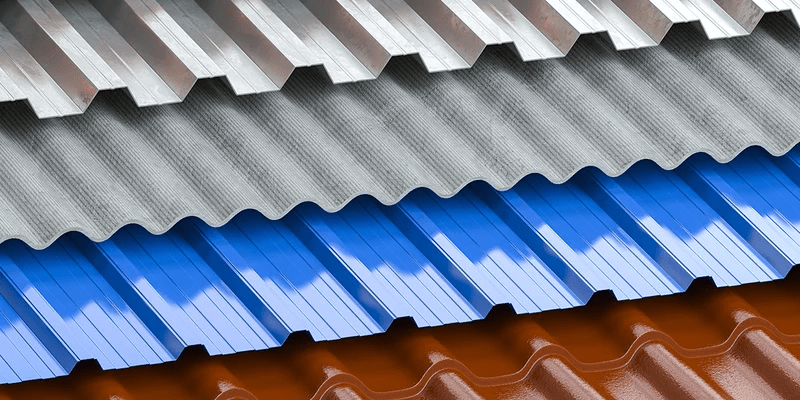

When considering metal roofing for your home or commercial building, one of the key aspects to understand is the thickness of the material. Gauge numbers are used to indicate the thickness of metal roofing panels, and 29 gauge is a common choice. But how thick is 29 gauge metal roofing exactly? This article will delve into the specifics of 29 gauge metal roofing, its applications, benefits, and considerations to help you make an informed decision.

Understanding Metal Roofing Gauges

Before answering the question of thickness, it’s important to understand what the gauge number means. In the context of metal roofing, the gauge number refers to the thickness of the metal. However, the gauge system is somewhat counterintuitive because a higher gauge number indicates a thinner metal. For example, 29 gauge metal is thinner than 26 gauge metal.

How Thick Is 29 Gauge Metal Roofing?

29 gauge metal roofing typically measures about 0.0142 inches (0.36 mm) in thickness. This may seem thin, but 29 gauge metal is commonly used for residential and some light commercial applications due to its balance of affordability, weight, and durability.

Applications of 29 Gauge Metal Roofing

29 gauge metal roofing is popular for a variety of applications. Let’s explore some common uses:

1. Residential Roofing:

- 29 gauge metal roofing is a popular choice for residential homes. It provides adequate protection against weather elements while being cost-effective.

- Its lighter weight makes it easier to handle and install, reducing labor costs and installation time.

Read too: Is It Reasonable to Ask the Seller to Replace the Roof?

2. Agricultural Buildings:

- Many barns, sheds, and other agricultural structures use 29 gauge metal roofing. It offers sufficient protection for these types of buildings without the need for a heavier gauge.

3. Light Commercial Buildings:

- Some light commercial buildings, such as small offices or retail spaces, may also use 29 gauge metal roofing. It provides a balance of strength and cost-efficiency suitable for these structures.

Benefits of 29 Gauge Metal Roofing

Now that we understand where 29 gauge metal roofing is commonly used, let’s explore the benefits it offers:

1. Cost-Effective:

- One of the most significant advantages of 29 gauge metal roofing is its cost-effectiveness. Thinner metal costs less to produce, which translates to lower prices for consumers.

2. Lightweight:

- The lighter weight of 29 gauge metal roofing panels makes them easier to transport, handle, and install. This can reduce labor costs and installation time.

3. Adequate Durability:

- While not as thick as some other gauges, 29 gauge metal roofing still offers adequate durability for many applications. It can withstand typical weather conditions and provide long-lasting protection.

4. Versatility:

- 29 gauge metal roofing is available in a wide range of colors and styles, allowing homeowners and builders to choose a design that complements their building’s aesthetic.

Considerations for Using 29 Gauge Metal Roofing

While 29 gauge metal roofing has many benefits, there are also some considerations to keep in mind:

1. Less Resistant to Severe Weather:

- Thinner metal is less resistant to severe weather conditions such as heavy hail or strong winds compared to thicker gauges. If you live in an area prone to such conditions, a thicker gauge might be more suitable.

2. Potential for Dents:

- Due to its thinner nature, 29 gauge metal roofing is more susceptible to dents from impacts, such as falling branches or heavy debris. Regular inspections and maintenance can help mitigate this issue.

3. Not Ideal for Heavy Snow Loads:

- In regions with heavy snowfall, the lighter weight of 29 gauge metal roofing might not provide adequate support. Thicker gauges are recommended for areas with significant snow loads.

Installation of 29 Gauge Metal Roofing

Proper installation is crucial to ensure the performance and longevity of 29 gauge metal roofing. Here are the key steps involved:

1. Preparing the Roof Deck:

- Before installing metal roofing panels, ensure the roof deck is in good condition. Any damaged or rotten sections should be repaired or replaced.

2. Installing the Underlayment:

- A quality underlayment is installed over the roof deck to provide an additional layer of protection against moisture. Synthetic underlayment or self-adhering membranes are common choices.

3. Attaching the Panels:

- 29 gauge metal roofing panels are then attached to the roof deck using appropriate fasteners. It’s important to follow the manufacturer’s guidelines for spacing and securing the fasteners.

4. Sealing the Seams:

- The seams between panels are sealed to prevent water infiltration. This step is crucial to maintaining the watertight integrity of the roof.

5. Installing Flashing:

- Flashing is installed around roof penetrations such as chimneys, skylights, and vents to ensure these areas are adequately protected from water intrusion.

Maintenance Tips for 29 Gauge Metal Roofing

To maximize the lifespan and performance of your 29 gauge metal roofing, regular maintenance is essential:

1. Regular Inspections:

- Conduct regular inspections, especially after severe weather events, to check for any signs of damage or wear. Look for loose or missing fasteners, dents, and scratches.

2. Cleaning:

- Keep the roof clean by removing debris, leaves, and branches that can trap moisture and lead to corrosion. Use a soft-bristle brush or low-pressure washer to clean the surface.

3. Addressing Minor Repairs:

- Address any minor repairs promptly to prevent them from becoming more significant issues. Replace damaged panels or fasteners as needed.

4. Checking Sealants:

- Check the condition of sealants around seams and flashing. Reapply or replace sealants as necessary to maintain a watertight seal.

Conclusion

Understanding how thick 29 gauge metal roofing is and its various applications, benefits, and considerations is crucial for making an informed decision. With a thickness of approximately 0.0142 inches, 29 gauge metal roofing offers a cost-effective and versatile option for many residential, agricultural, and light commercial applications. While it may not be the best choice for areas with severe weather or heavy snow loads, it provides adequate durability and ease of installation for many other scenarios.

Proper installation and regular maintenance are key to ensuring the longevity and performance of your 29 gauge metal roof. By following these guidelines, you can enjoy the benefits of a durable, cost-effective roofing solution that enhances the aesthetic appeal and functionality of your building.

Leave a Reply