When it comes to modern construction, metal decking has become a popular choice for roofing systems due to its strength, durability, and versatility. Metal deck roofs are not only known for their structural integrity, but they also offer aesthetic appeal and sustainability benefits. Understanding the intricacies of Metal Deck Roof Detail is essential for architects, contractors, and homeowners looking for a long-lasting and energy-efficient roofing solution.

In this article, we will explore the details of metal deck roofs, including their design, installation process, benefits, and the key factors to consider when selecting the right type of metal decking for your project.

What Is a Metal Deck Roof?

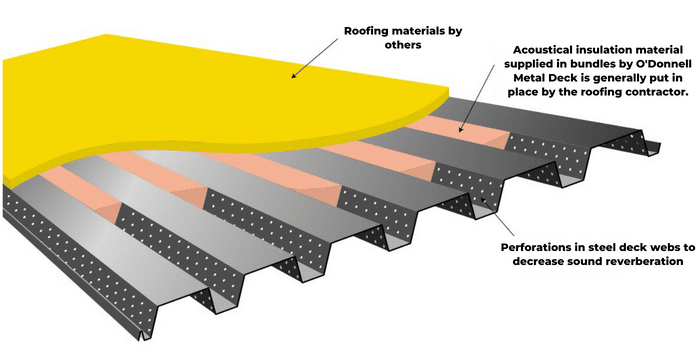

A metal deck roof refers to a structural element made from steel or aluminum sheets that are laid over roof framing to form a solid, durable, and lightweight roof surface. These decks can serve as the foundation for various roofing materials, such as insulation layers, waterproof membranes, and other surface finishes.

The Metal Deck Roof Detail plays a critical role in ensuring the overall stability and longevity of the roof. Metal decking is most commonly used in commercial, industrial, and institutional buildings, but its advantages have made it increasingly popular in residential construction as well.

Read too: Hail Damage Roof Repair: Essential Guide to Restoring Your Home’s Protection

Types of Metal Deck Roofing

There are several types of metal deck roofing systems available, each designed for specific purposes and architectural needs. Common types include:

- Roof Decking: This type of decking provides structural support for roofing systems. It is typically used as the base for built-up roofing, single-ply roofing, or other types of roofing membranes.

- Composite Decking: Composite metal decking combines concrete and steel to create a strong, durable roof. This option is popular for buildings requiring extra strength and load-bearing capacity.

- Corrugated Decking: Corrugated metal decking is characterized by its wave-like pattern, which enhances its strength and structural integrity. It’s often used in industrial and commercial projects.

Metal Deck Roof Detail: Components and Considerations

When discussing Metal Deck Roof Detail, it’s essential to understand the components that contribute to the overall performance and functionality of the roof. Each of these elements plays a specific role in ensuring the roof’s durability, insulation, and weather resistance.

Key Components of Metal Deck Roof Detail

1. Metal Deck Panels

The primary component of any metal deck roof is the metal deck panel itself. These panels come in different profiles, thicknesses, and finishes depending on the requirements of the structure. The panels are typically made of galvanized steel or aluminum, which offers high resistance to corrosion and rust.

Metal deck panels are designed to provide a rigid surface for the roofing materials while distributing loads evenly across the structure. The most common profiles for these panels include:

- Corrugated: These panels have a wavy design that increases structural strength and prevents sagging.

- Ribbed: Ribbed panels have flat sections with raised ridges, offering improved load-bearing capabilities and drainage.

- Standing Seam: Standing seam panels feature interlocking seams that prevent water penetration, making them ideal for weatherproofing the roof.

2. Fasteners and Connectors

Fasteners and connectors are crucial to holding the metal deck panels securely in place. These components ensure that the roof remains structurally sound, even under heavy wind or rain conditions. Stainless steel screws, bolts, and anchors are commonly used in metal deck roofing systems to provide long-lasting durability.

3. Insulation

Insulation is an important part of the Metal Deck Roof Detail, as it enhances energy efficiency by reducing heat transfer through the roof. And insulation can be installed directly onto the metal deck panels before the application of the roofing membrane or top layer. Common types of insulation used in metal deck roofs include:

- Rigid Foam Insulation: Offers excellent thermal performance and is resistant to moisture.

- Spray Foam Insulation: Expands to fill gaps and provides an airtight barrier.

- Fiberglass Insulation: Lightweight and effective, but it may require additional protection from moisture.

4. Waterproof Membrane

To prevent water infiltration and protect the building from moisture damage, a waterproof membrane is often applied over the insulation layer. This membrane forms a barrier that keeps water from seeping into the building, even during heavy rainstorms. Common waterproofing materials include synthetic rubber (EPDM), thermoplastic (TPO), or modified bitumen.

5. Finishing Materials

The top layer of the roof deck is where aesthetics come into play. Metal deck roofs can be finished with various materials, depending on the desired appearance and performance characteristics. Some options include:

- Metal Roofing Sheets: These sheets are available in various colors and finishes to match the architectural style of the building.

- Shingles or Tiles: For a more traditional look, metal deck roofs can be finished with shingles or tiles made from clay, asphalt, or concrete.

Installation Process for Metal Deck Roofs

Installing a metal deck roof involves several steps that require precision and attention to detail. Proper installation is critical for ensuring the longevity and performance of the roof. Below is an overview of the installation process for a typical metal deck roof system.

Step 1: Preparing the Roof Structure

Before installing the metal deck, the roof structure (trusses or beams) must be prepared. The structure needs to be level, properly aligned, and capable of supporting the weight of the decking and any additional loads. This step ensures that the roof will remain stable and secure over time.

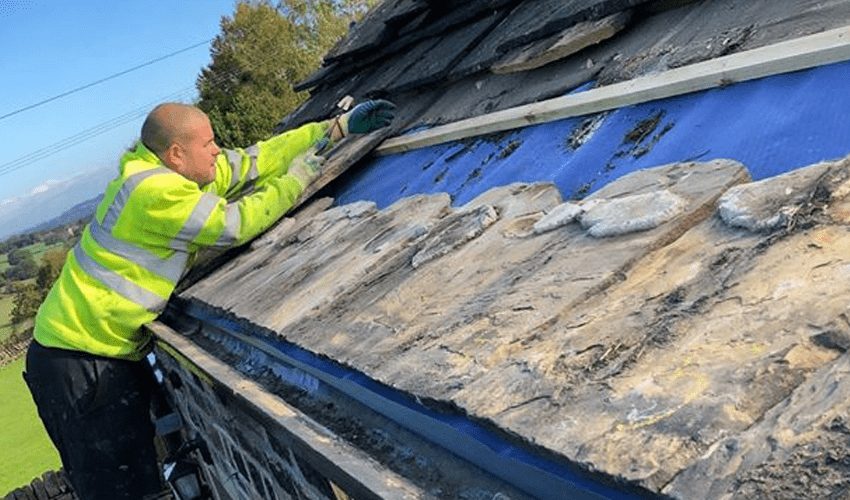

Step 2: Laying the Metal Deck Panels

The metal deck panels are then laid over the roof structure. Each panel is carefully aligned and fastened using stainless steel screws or bolts. The panels are overlapped at the seams to create a continuous surface that prevents water from penetrating the roof.

Step 3: Adding Insulation

Once the metal deck panels are securely in place, the next step is to add insulation. The insulation is installed directly onto the metal deck, creating a thermal barrier that improves the building’s energy efficiency. Depending on the type of insulation, this step may involve cutting the insulation to fit the contours of the roof.

Step 4: Applying the Waterproof Membrane

A waterproof membrane is applied over the insulation to provide an additional layer of protection against water infiltration. This membrane is usually adhered or mechanically fastened to the deck and seams are sealed to prevent leaks.

Step 5: Finishing the Roof

The final step in the installation process is to apply the finishing material, such as metal roofing sheets or shingles. This layer completes the roof’s aesthetic appeal while adding extra protection against weather and environmental elements.

Benefits of Metal Deck Roofs

1. Durability and Longevity

One of the primary benefits of metal deck roofs is their exceptional durability. Metal roofing materials are resistant to harsh weather conditions, including heavy rain, snow, hail, and high winds. Additionally, metal deck roofs have a long lifespan, often lasting 40-70 years with proper maintenance.

2. Energy Efficiency

Metal decks, when combined with the right insulation, can significantly improve the energy efficiency of a building. Metal reflects sunlight, reducing the amount of heat absorbed into the building, which in turn lowers cooling costs in hot climates. Paired with proper insulation, metal deck roofs help maintain comfortable indoor temperatures year-round.

3. Sustainability

Metal deck roofing systems are environmentally friendly. Metal is 100% recyclable, making it an excellent choice for eco-conscious homeowners and builders. Many metal roofing materials also contain recycled content, further reducing the environmental impact.

4. Lightweight and Easy to Install

Compared to other roofing materials, metal decking is lightweight, which reduces the overall load on the structure. This feature makes installation easier and faster, reducing labor costs and project timelines.

5. Fire Resistance

Metal deck roofs are non-combustible, which makes them highly fire-resistant. This is a valuable safety feature for both residential and commercial buildings, especially in areas prone to wildfires.

Conclusion: Why Metal Deck Roofs Are a Smart Choice

In conclusion, understanding Metal Deck Roof Detail is essential for anyone considering this type of roofing system for their project. Metal deck roofs offer numerous benefits, including durability, energy efficiency, and sustainability. They are easy to install, require minimal maintenance, and can enhance the aesthetic and functional value of any building.

Whether you’re constructing a commercial building or upgrading your home, a metal deck roof can provide a cost-effective, long-lasting solution that stands up to the elements while adding value and beauty to your property.

Leave a Reply