When it comes to constructing or renovating a building, ensuring its structural integrity and longevity is of utmost importance. One crucial element in achieving this goal is the proper installation of expansion joints. Among various types of construction joints, metal roof expansion joints play a vital role in accommodating the natural movement of a building due to thermal expansion and contraction. This article delves into the significance of metal roof expansion joint details, their installation process, and how they ensure durability and flexibility for buildings.

Understanding Metal Roof Expansion Joint Details

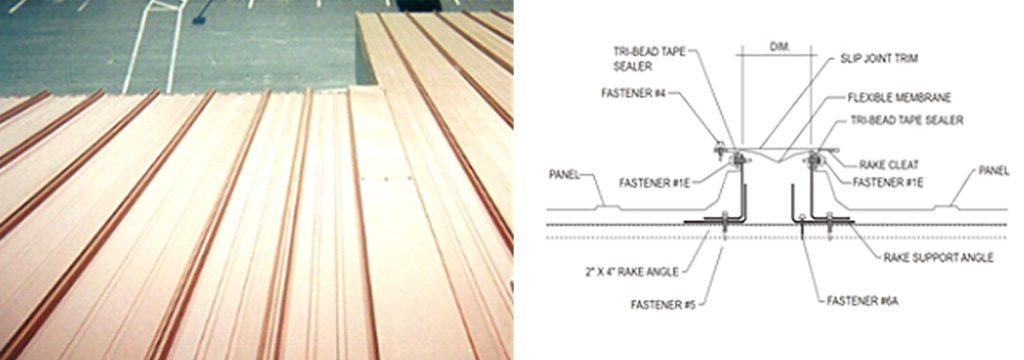

Metal roof expansion joint details are specially designed components installed in the roof system to allow for movement caused by temperature fluctuations and other external factors. These joints are critical in preventing structural damage, such as buckling or distortion, which may occur when the building materials expand or contract due to changes in temperature or settling of the foundation.

The Importance of Flexibility in Metal Roofing

Metal roofs are highly regarded for their durability and long lifespan. However, without the incorporation of expansion joints, even metal roofs can be susceptible to stress and damage over time. The ability to expand and contract freely without constraint is crucial in ensuring the roof’s stability and preventing leaks or gaps from developing between roof panels.

Types of Metal Roof Expansion Joint Details

- Roof Ridge Expansion Joints: Roof ridges are particularly susceptible to expansion and contraction forces due to their elevated position and exposure to the elements. Ridge expansion joints are installed at the peak of the roof to allow for upward and downward movement of the roof panels.

- Roof Eave Expansion Joints: The eave is the lowest edge of the roof, often where the roof meets the walls or overhangs. Eave expansion joints are essential for accommodating lateral movement and maintaining the integrity of the roof-to-wall connection.

- Roof Expansion Joint Covers: These are protective covers that are placed over the expansion joints to shield them from debris, water, and other potential sources of damage. Expansion joint covers help prolong the life of the joints and maintain their effectiveness.

Proper Installation Process

The installation of metal roof expansion joints requires precision and attention to detail. Improper installation can compromise the joints’ functionality and lead to costly repairs down the line. Here are some key steps in the proper installation process:

- Site Inspection: Before installation, thoroughly inspect the roof and building structure to determine suitable expansion joint locations. During this assessment, consider factors such as roof size, roof pitch, and local climate.

- Material Selection: Choose high-quality materials capable of withstanding weather exposure and temperature changes for the expansion joints. Stainless steel, aluminum, and EPDM rubber are commonly used materials for these applications.

- Sealant Application: They apply a flexible sealant to the edges of the expansion joints to create a watertight barrier. This prevents water infiltration and protects the roof structure from potential damage caused by leaks.

- Fastening and Securement: Proper fastening secures expansion joint covers during roof movement. They commonly use stainless steel screws or clips to secure the covers to the roof surface.

- Regular Maintenance: After installing, conduct regular inspections and maintenance to identify any signs of wear or damage. Carry out prompt repairs or replacements as needed to maintain the joints’ effectiveness.

Conclusion

Metal roof expansion joint details are vital components in ensuring the longevity and durability of metal roofs. The ability to accommodate natural building movements is essential in preventing structural damage and maintaining a watertight roof system. Understanding expansion joint details and following proper installation protects building investments, ensuring well-maintained, reliable metal roofs for years to come.

Leave a Reply