When it comes to installing a metal roof, ensuring proper furring strip spacing is crucial for a successful and durable installation. Furring strips provide a solid base for attaching the metal roofing panels, allowing for proper ventilation, thermal insulation, and structural stability. In this article, we will explore the importance of furring strip spacing in metal roof installations and discuss the factors to consider for an effective and long-lasting roofing system.

Understanding Furring Strip Spacing:

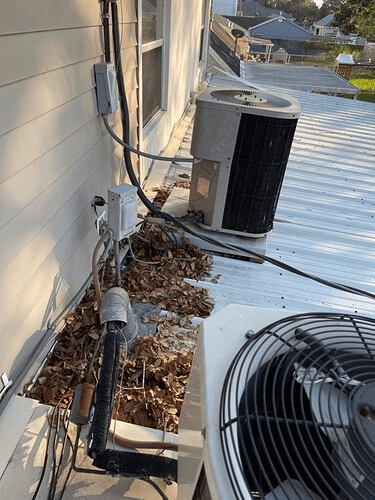

Furring strips are horizontal strips of wood or metal that are installed over the roof deck to create a uniform surface for attaching the metal roofing panels. The spacing between these strips plays a vital role in the overall performance and longevity of the metal roof. Proper furring strip spacing ensures adequate support, reduces the risk of panel distortion, and allows for proper water drainage and ventilation.

Factors to Consider for Furring Strip Spacing:

- Roofing System Design and Profile: The design and profile of the metal roofing system influence the recommended furring strip spacing. Standing seam metal roofs, for example, typically require narrower spacing compared to corrugated metal roofs. Consult the manufacturer’s guidelines or technical specifications to determine the appropriate spacing based on the specific roofing system being installed.

- Roof Slope and Local Weather Conditions: Roof slope and local weather conditions impact furring strip spacing. Steeper roofs and areas with heavy rainfall need closer spacing for water shedding and to prevent infiltration.

- Building Codes and Regulations: Local building codes and regulations may specify the minimum requirements for furring strip spacing. It is essential to comply with these guidelines to ensure the roof meets safety standards and maintains warranty coverage.

- Panel Length and Thickness: The length and thickness of the metal roofing panels also influence the furring strip spacing. Longer and heavier panels may require closer spacing to ensure proper support and prevent sagging or buckling.

The Benefits of Proper Furring Strip Spacing:

Proper furring strip spacing offers several benefits for metal roof installations:

- Structural Stability: Sufficient furring strip spacing stabilizes metal roofing panels, minimizing movement, sagging, and deformation risks.

- Enhanced Ventilation: Proper spacing allows for air circulation between the metal roof and the underlying structure, reducing the risk of condensation and promoting better ventilation, which can help prevent moisture-related issues.

- Improved Water Drainage: Proper furring strip spacing ensures efficient water drainage, reducing pooling and potential leaks.

- Prevents Thermal Bridging: Furring strips reduce thermal bridging, improving energy efficiency and limiting heat transfer between the metal roof and roof deck.

Conclusion:

Metal roof furring strip spacing is a critical consideration for a successful and durable roof installation. The spacing between the furring strips impacts the structural stability, ventilation, water drainage, and overall performance of the metal roof. Consider roofing system design, roof slope, weather conditions, building codes, and panel specifications when determining appropriate spacing. By ensuring proper furring strip spacing, you can achieve a long-lasting and efficient metal roof that provides protection and adds value to your property.

Leave a Reply