When planning a roofing project, especially with corrugated metal roofs, one of the crucial factors to consider is the minimum pitch required. The minimum pitch corrugated metal roof refers to the least slope angle needed to ensure the roof performs effectively, preventing water accumulation and ensuring durability. This guide will delve into what minimum pitch means, why it’s important, and how to determine and manage it for your project.

What is Minimum Pitch for Corrugated Metal Roofs?

The term minimum pitch refers to the lowest angle at which a roof can be installed while still functioning correctly. For corrugated metal roofs, this pitch is essential for effective drainage and longevity. The pitch is usually measured in degrees or as a ratio of vertical rise to horizontal run.

Read too: Decoding Timelines: How Long Does It Take To Replace A Roof and What to Expect

Why Minimum Pitch Matters

- Water Drainage: Adequate pitch ensures that water flows off the roof efficiently. Without the correct pitch, water can pool on the roof, leading to leaks, rust, and potential structural damage.

- Snow and Ice Management: In colder climates, proper pitch helps prevent snow and ice buildup, which can add weight to the roof and lead to potential structural issues.

- Roof Longevity: A roof installed at the proper pitch is less likely to experience issues such as leaking or premature wear. This contributes to the overall lifespan of the roofing system.

- Code Compliance: Building codes often specify minimum pitch requirements for different types of roofs, including corrugated metal. Adhering to these codes is essential for safety and legal compliance.

Minimum Pitch Requirements for Corrugated Metal Roofs

Standard Minimum Pitch

The standard minimum pitch for corrugated metal roof is typically around 5 degrees or 1:12, but this can vary depending on the specific type of corrugated metal and the manufacturer’s recommendations. It’s important to consult with your roofing supplier or contractor to confirm the minimum pitch for your chosen material.

Factors Influencing Minimum Pitch

- Type of Corrugated Metal: Different types of corrugated metal, such as galvanized steel, aluminum, or zinc-coated steel, may have varying minimum pitch requirements. Always refer to the manufacturer’s guidelines for specific information.

- Local Climate: The local climate can influence the necessary pitch. Areas with heavy rainfall or snowfall may require a steeper pitch to handle the additional load and ensure proper drainage.

- Building Code Regulations: Building codes and regulations may dictate minimum pitch requirements for corrugated metal roofs in your area. Ensure you’re aware of and comply with these regulations to avoid potential issues.

- Roof Design and Complexity: The design of your roof, including its size, shape, and complexity, can affect the required pitch. Complex roof designs may require different pitch considerations compared to simple, straightforward roofs.

How to Determine the Minimum Pitch for Your Roof

1. Consult Manufacturer Guidelines

Start by consulting the manufacturer’s guidelines for the corrugated metal roofing you plan to use. Manufacturers provide specific recommendations for pitch based on the material’s properties and performance characteristics.

2. Consider Local Building Codes

Review local building codes and regulations to determine any minimum pitch requirements that apply to your roofing project. Compliance with these codes is essential for safety and legal reasons.

3. Assess Environmental Factors

Evaluate the environmental factors in your area, such as average rainfall, snowfall, and wind conditions. This assessment will help determine if a higher pitch is needed to handle the local weather conditions effectively.

4. Consult with a Roofing Professional

A roofing professional can provide valuable insights and recommendations based on their experience and expertise. They can assess your specific situation and help determine the appropriate pitch for your corrugated metal roof.

Installing Corrugated Metal Roofs at the Correct Pitch

1. Preparation and Planning

Proper preparation is key to a successful installation. Ensure that your roof structure is capable of supporting the corrugated metal roof and that any necessary adjustments are made to achieve the correct pitch.

2. Roof Decking and Underlayment

Install appropriate roof decking and underlayment before laying the corrugated metal sheets. The decking should be smooth and level, and the underlayment should be suitable for the type of metal roofing used.

3. Laying Corrugated Metal Sheets

Begin laying the corrugated metal sheets from the bottom of the roof and work your way up. Ensure that each sheet is properly aligned and overlaps with the previous one to create a watertight seal.

4. Securing and Sealing

Secure the corrugated metal sheets using the recommended fasteners and sealants. Proper sealing is crucial to prevent leaks and ensure the longevity of the roof.

5. Final Inspection

After installation, conduct a thorough inspection to ensure that the roof is installed correctly and that the pitch is consistent throughout. Address any issues or adjustments needed before completing the project.

Maintenance and Care for Corrugated Metal Roofs

Proper maintenance is essential to ensure the longevity and performance of your corrugated metal roof. Here are some tips for maintaining your roof:

1. Regular Inspections

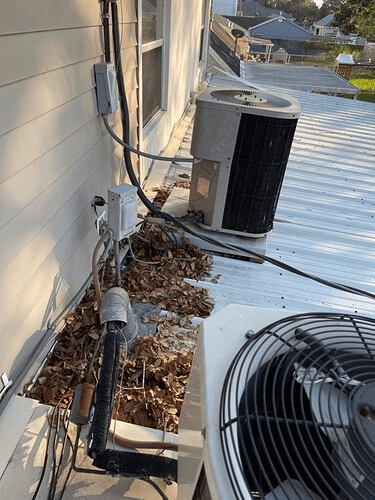

Schedule regular inspections to check for signs of wear, damage, or issues with the pitch. Address any problems promptly to prevent further damage.

2. Clean Gutters and Downspouts

Keep gutters and downspouts clean and free of debris to ensure proper water drainage. Clogged gutters can cause water to back up and affect the performance of your roof.

3. Check for Damage

Regularly inspect your roof for any signs of damage, such as dents, rust, or loose fasteners. Address any issues immediately to maintain the integrity of the roof.

4. Maintain Proper Pitch

Ensure that the roof pitch remains consistent and within the recommended range. Any changes or settling of the roof structure should be addressed to maintain proper drainage and performance.

Conclusion

Understanding and managing the minimum pitch corrugated metal roof is crucial for ensuring the effectiveness and durability of your roofing system. By following manufacturer guidelines, considering local building codes, and consulting with professionals, you can achieve the optimal pitch for your roof and enjoy long-lasting performance. Proper installation and regular maintenance will further enhance the longevity and functionality of your corrugated metal roof, providing reliable protection for your home.

Leave a Reply