Minimum Slope For Corrugated Metal Roof. When planning to install a corrugated metal roof, one of the critical factors to consider is the roof’s slope. Understanding the minimum slope required for corrugated metal roofing can ensure optimal performance, longevity, and protection for your home or building. This article will guide you through the necessary considerations, best practices, and practical advice for achieving the correct slope for your corrugated metal roof.

Understanding Corrugated Metal Roofing

What is Corrugated Metal Roofing?

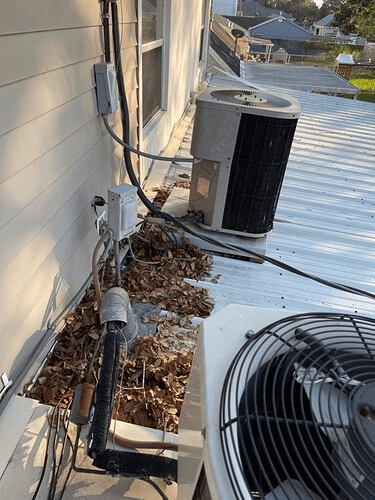

Corrugated metal roofing consists of metal panels with a wavy or ridged pattern. These panels are designed to be both lightweight and durable, offering a long-lasting roofing solution that can withstand harsh weather conditions. Typically made from steel, aluminum, or copper, corrugated metal roofs are known for their resistance to corrosion, fire, and high winds.

Read too: How To Replace A Mobile Home Roof: Step-by-Step Guide for Homeowners

Benefits of Corrugated Metal Roofing

- Durability: Corrugated metal roofs are highly resistant to extreme weather conditions and can last for decades with proper maintenance.

- Low Maintenance: The design of corrugated metal roofing reduces the accumulation of debris and makes it easier to clean.

- Energy Efficiency: Reflective coatings on metal panels can help reduce cooling costs by reflecting solar heat.

- Aesthetic Appeal: Available in various colors and finishes, corrugated metal roofs can enhance the visual appeal of your property.

Importance of Roof Slope

What is Roof Slope?

The roof slope, also known as the pitch, refers to the angle of the roof’s surface. It is typically expressed as a ratio or a percentage, representing the vertical rise per unit of horizontal run. For example, a 4:12 slope means the roof rises 4 inches for every 12 inches of horizontal distance.

Why Slope Matters for Corrugated Metal Roofs

The slope of a roof plays a crucial role in determining its effectiveness and longevity:

- Water Drainage: Proper slope ensures that rainwater and snow are effectively channeled off the roof, preventing ponding and potential leaks.

- Structural Integrity: A suitable slope helps distribute weight evenly across the roof structure, reducing the risk of stress and damage.

- Ventilation: Adequate slope can facilitate better airflow and ventilation within the roofing system.

Minimum Slope For Corrugated Metal Roof

Recommended Minimum Slope

For corrugated metal roofs, the recommended minimum slope typically ranges from 2:12 to 4:12. However, specific recommendations can vary based on factors such as the type of metal used, the roofing system design, and local building codes.

- 2:12 Slope: This is the minimum slope often recommended for corrugated metal roofs, especially for applications where proper drainage is critical. Roofs with this slope may require additional measures to ensure water runoff and prevent leaks.

- 3:12 to 4:12 Slope: These slopes are more common and provide better drainage and performance. They are generally suitable for residential and commercial applications where enhanced protection against water accumulation is needed.

Factors Affecting Slope Requirements

- Roof Material: Different metals and panel designs may have specific slope requirements. Always refer to the manufacturer’s guidelines for your chosen material.

- Climate and Weather Conditions: Areas with heavy rainfall or snowfall may require steeper slopes to handle water and snow loads effectively.

- Roof Design and Configuration: Complex roof designs with multiple valleys or hips may need adjustments to the slope to ensure proper drainage.

Local Building Codes

It’s essential to check local building codes and regulations, as they may specify minimum slope requirements for corrugated metal roofs in your area. Compliance with these codes ensures that your roof meets safety standards and performs as expected.

Installation Tips for Achieving the Correct Slope

Proper Roof Framing

Ensure that the roof framing and structure are designed to support the desired slope. Properly spaced rafters and supports will help maintain the roof’s integrity and performance.

Correct Panel Installation

Follow the manufacturer’s installation instructions to ensure that the corrugated metal panels are installed correctly. Overlapping panels and securing them with appropriate fasteners will prevent leaks and improve durability.

Sealing and Flashing

Use high-quality sealants and flashing materials to seal joints, seams, and penetrations. Proper sealing is crucial for preventing water infiltration and maintaining the roof’s performance.

Regular Maintenance

Regularly inspect and maintain your corrugated metal roof to address any issues that may arise. Check for signs of wear, rust, or damage, and perform necessary repairs to keep the roof in good condition.

Common Issues with Inadequate Roof Slope

Water Ponding

A roof with insufficient slope may experience water ponding, where water collects in low areas instead of draining away. This can lead to leaks, mold growth, and damage to the roof structure.

Ice Dams

In colder climates, a low slope roof may be prone to ice dam formation, where ice builds up along the roof’s edge, preventing proper drainage and causing water to back up under the roofing material.

Increased Wear and Tear

Roofs with inadequate slopes may experience increased wear and tear due to the added stress from trapped water and debris. This can shorten the lifespan of the roofing material and lead to costly repairs.

Conclusion

Understanding the minimum slope required for corrugated metal roofs is essential for ensuring optimal performance and longevity. By adhering to recommended slope guidelines, considering local building codes, and following proper installation practices, you can achieve a roof that effectively channels water, maintains structural integrity, and provides long-lasting protection for your home or building.

Whether you are planning a new installation or evaluating an existing roof, paying attention to the slope will help you make informed decisions and ensure that your corrugated metal roof performs as expected.

Leave a Reply