When installing a metal roof, one of the most important considerations is purlin spacing. This structural component plays a vital role in ensuring the stability, durability, and performance of your metal roof. Whether you’re building a new roof or retrofitting an existing one, understanding the correct purlin spacing for a metal roof is critical to achieving a successful outcome.

In this guide, we’ll dive into everything you need to know about purlin spacing metal roof installation. We’ll cover what purlins are, their role in roofing, how to determine the correct spacing, and the factors that can influence your decision.

What is Purlin Spacing in a Metal Roof?

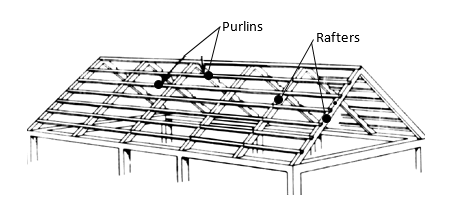

Before we delve into the details, let’s first clarify what purlin spacing means in the context of a metal roof. Purlins are horizontal support structures that are placed on top of the rafters or trusses in a roof. These beams help to support the weight of the roof panels and provide a solid base for the roof sheeting to be attached to.

Read too: Decoding Timelines: How Long Does It Take To Replace A Roof and What to Expect

Purlin spacing refers to the distance between each purlin. This measurement is critical because it directly affects the roof’s load-bearing capacity, performance, and longevity. If the spacing is too wide, the roof may not have enough support, which could lead to sagging or collapse. If the spacing is too close, you may be wasting materials and increasing costs unnecessarily.

Why Purlin Spacing is Crucial for Metal Roofs

When installing a metal roof, ensuring that the purlin spacing is correct is vital to the overall health and performance of the roof system. Here’s why purlin spacing metal roof is such a critical component:

1. Load Distribution

Properly spaced purlins ensure that the load of the roof is evenly distributed. Metal roofs are designed to withstand various stresses such as wind, rain, and snow. The purlins act as the framework that helps the roof handle these forces. If the spacing is incorrect, you risk concentrating loads in certain areas, which can weaken the overall structure.

2. Roof Panel Support

Since metal roof panels are typically installed in sheets, they need a solid support system to prevent bending, bowing, or cracking. Correct purlin spacing ensures that the metal roof panels have sufficient support, especially under adverse weather conditions. Without proper support, the panels may flex and degrade over time, leading to leaks or damage.

3. Preventing Roof Sagging

Sagging can occur when there is insufficient support for the roof panels, and over time this can cause a roof to fail. By setting the purlin spacing correctly, you ensure that the weight of the roof is adequately supported and that the roof remains level and sturdy, even as it ages.

4. Maximizing Material Efficiency

Purlin spacing not only affects the structural integrity of the roof, but it also plays a role in determining how much material is required for the roof installation. Too many purlins can lead to unnecessary costs, while too few can compromise the roof’s stability. Striking the right balance between spacing and material use ensures both a durable and cost-effective solution.

Factors Influencing Purlin Spacing in a Metal Roof

Several factors influence the purlin spacing for a metal roof. The correct spacing is determined by variables such as the type of metal roofing material, the roof’s slope, the environmental conditions, and more. Here’s a breakdown of the most significant factors to consider:

1. Type of Metal Roofing Material

Different types of metal roofing materials require different levels of support, and this will affect the purlin spacing. For example:

- Corrugated metal panels are commonly used in metal roofing and tend to require tighter purlin spacing due to their thinner gauge.

- Standing seam metal roofs, which are thicker and more rigid, may allow for wider spacing between purlins.

- Steel roofs generally have more strength and may require fewer purlins compared to lightweight materials like aluminum.

2. Roof Load Requirements

The load-bearing requirements of the roof also affect purlin spacing. This includes both live loads (temporary forces such as snow, rain, or foot traffic) and dead loads (permanent forces like the weight of the roofing material itself). If you live in an area with heavy snow or frequent storms, tighter purlin spacing may be necessary to prevent damage or collapse.

3. Roof Slope

The slope of the roof (also known as pitch) will impact the purlin spacing as well. A steeper roof can sometimes allow for wider purlin spacing because the angle reduces the direct impact of weather forces, such as rainwater pooling or snow accumulation. Conversely, a flatter roof may need tighter spacing to accommodate greater weight or water retention.

4. Wind Load

Regions that experience high wind speeds must account for wind uplift, which can exert powerful forces on a roof, pulling it away from the building. In these areas, purlin spacing must be adjusted to provide additional support against uplift. Metal roofs in hurricane-prone or tornado-prone regions typically require tighter purlin spacing to ensure the roof stays anchored during extreme weather.

5. Span of the Roof

The overall span of the roof can also dictate the correct purlin spacing. Larger spans will often require more purlins to provide sufficient support across the entire roof area. In some cases, additional purlins may be added in areas where structural loads are greater, such as near ridges, eaves, or valleys.

Guidelines for Determining Purlin Spacing in Metal Roofs

While the specific requirements for purlin spacing vary depending on the factors mentioned above, there are some general guidelines that homeowners and contractors can follow when planning a metal roof installation:

1. Standard Spacing for Metal Roofs

For most metal roofing systems, purlins are typically spaced between 18 to 36 inches apart. However, this spacing can vary depending on the type of metal, the gauge of the material, and the load requirements. For example:

- Lightweight metal roofing panels like aluminum or thinner corrugated sheets may require purlin spacing of 18 to 24 inches.

- Heavier-duty materials such as standing seam or thicker gauge steel can usually have wider spacing, ranging from 24 to 36 inches.

2. Adjusting Spacing Based on Load Conditions

As mentioned, environmental factors like snow loads or wind uplift will affect the recommended purlin spacing. In regions where the roof is likely to bear significant snow loads, you may need to reduce the spacing to as close as 12 to 18 inches. Similarly, high wind areas may require tighter spacing to prevent uplift.

3. Consulting Manufacturer Guidelines

Each metal roofing product comes with specific installation instructions from the manufacturer. These guidelines typically include recommendations for purlin spacing based on the material’s properties and intended usage. Always consult the manufacturer’s recommendations before finalizing your roof’s purlin spacing plan to ensure it complies with industry standards.

Installation Best Practices for Purlin Spacing in Metal Roofs

To ensure your metal roof is installed properly, following best practices for purlin spacing is essential. Here are some tips to keep in mind:

1. Start with a Detailed Plan

Before installation begins, create a detailed plan that outlines the placement of purlins, taking into account the roof’s slope, span, load requirements, and the type of metal being used. This plan will serve as a roadmap during installation and help to avoid errors that could lead to instability or inefficiency.

2. Ensure Proper Fastening

Proper fastening of the purlins to the rafters or trusses is essential to maintain roof integrity. Use the correct size and type of fasteners for your specific roofing system. Also, make sure the purlins are securely attached to the rafters to prevent movement or shifting during adverse weather conditions.

3. Use High-Quality Materials

The quality of the purlins themselves is crucial. Steel purlins are the most common choice for metal roofs due to their strength and durability. When selecting materials, opt for high-quality, corrosion-resistant products that will provide long-term stability for your roof.

4. Inspect Regularly

Even after installation, regular inspections of the purlins and roof structure are important. Over time, factors like wear and tear, wind, and moisture can affect the roof’s structural integrity. Make sure that purlins remain securely in place and that there are no signs of weakening or damage.

Conclusion

Correct purlin spacing for a metal roof is one of the most critical factors in ensuring a roof that performs well and lasts for decades. By understanding the role of purlins and how spacing impacts load distribution, support, and durability, you can make informed decisions during the installation process. Consider factors such as the type of metal roofing material, the roof’s slope, and local environmental conditions when determining the right spacing for your roof.

Following best practices and manufacturer guidelines for purlin spacing will result in a strong, long-lasting metal roof that stands up to the elements and provides excellent value for your investment.

Leave a Reply