When it comes to installing a metal roof, one of the critical decisions you’ll need to make is choosing the right screw pattern. The screw pattern, or the layout and spacing of screws used to secure the metal panels to the roof deck, is essential for ensuring the longevity and performance of your roof. In this article, we’ll explore the factors to consider when selecting a screw pattern for your metal roof.

Understanding Metal Roofing

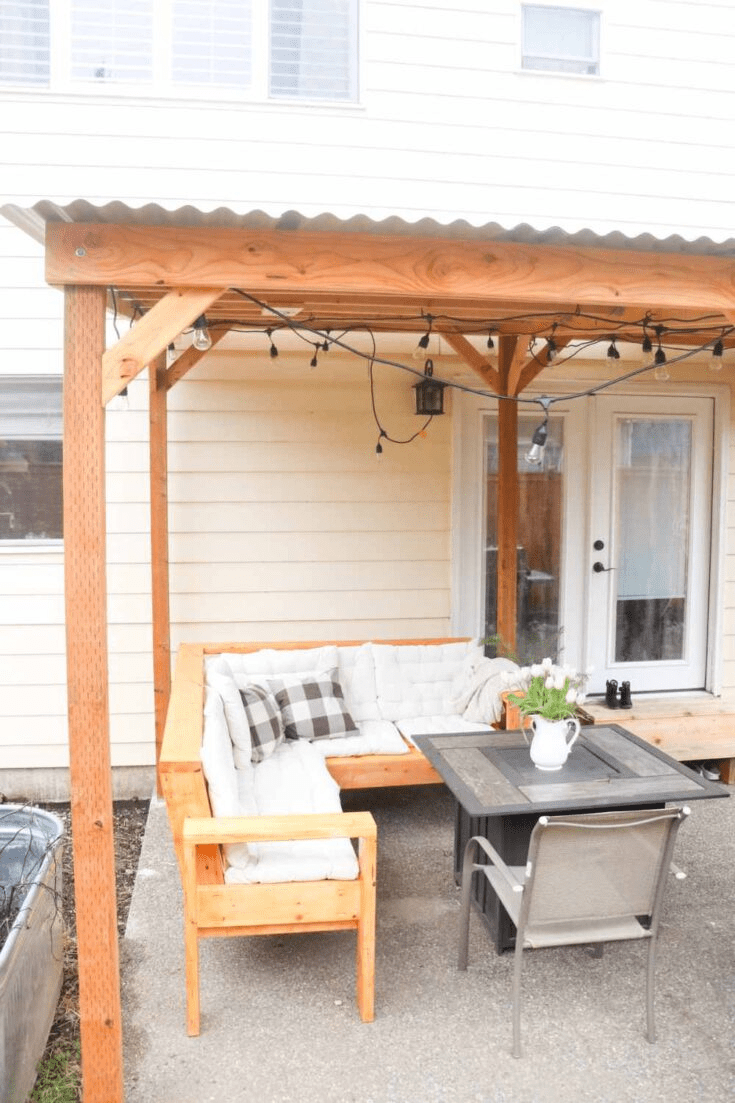

Before we dive into screw patterns, let’s briefly discuss metal roofing. Metal roofs have gained popularity due to their durability, energy efficiency, and aesthetic appeal. They come in various materials, including steel, aluminum, copper, and zinc, each with its unique characteristics. However, regardless of the material, proper installation is crucial to maximize the benefits of a metal roof.

Why Screw Patterns Matter

The screw pattern plays a vital role in a metal roof’s ability to withstand various environmental factors, including wind, rain, and snow. It also affects the roof’s resistance to leaks and its overall structural integrity. Here are some key considerations when determining the right screw pattern for your metal roof:

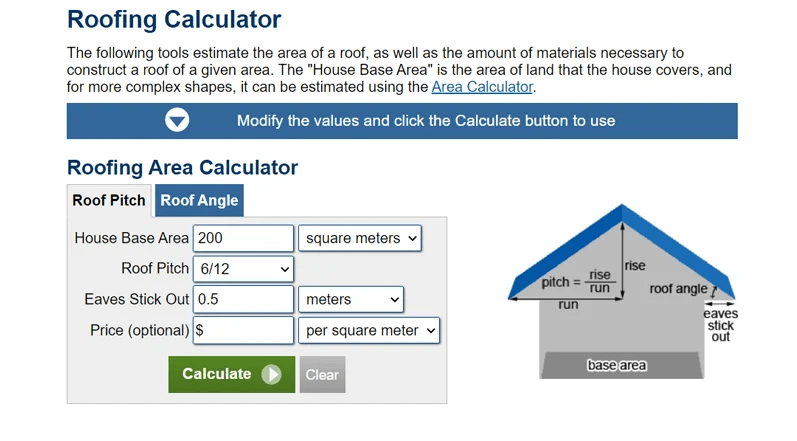

1. Roof Slope and Pitch

The slope or pitch of your roof is a significant factor in selecting the appropriate screw pattern. Steeper roofs may require more fasteners to prevent panels from slipping or separating during extreme weather conditions. The pitch also affects the angle at which screws are driven into the roof deck.

2. Local Climate

Your geographical location and the local climate should influence your screw pattern choice. Areas prone to high winds, heavy snow loads, or frequent rainstorms may require more closely spaced screws to enhance the roof’s resistance to these elements.

3. Panel Type and Profile

Different types of metal panels have varying load-bearing capacities. The screw pattern should be compatible with the panel type you choose. Some panels have specific recommendations from manufacturers regarding screw spacing and placement.

4. Fastener Type

The type of fastener you use also affects the screw pattern. Common fastener options include screws with neoprene washers or gaskets, which create a watertight seal. The spacing and placement of these fasteners should align with your chosen screw pattern.

5. Local Building Codes

Always check local building codes and regulations regarding metal roof installation. Some areas may have specific requirements for screw patterns and other installation details.

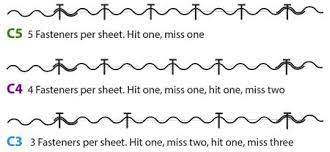

Common Screw Patterns

While there isn’t a one-size-fits-all screw pattern for metal roofing, some common patterns are widely used:

1. Straight Line Pattern: In this pattern, screws are aligned in straight lines along the roof’s length, creating a clean and uniform appearance. It’s suitable for roofs with minimal slope.

2. Staggered Pattern: Staggered patterns alternate the placement of screws from one row to the next. This pattern offers excellent wind resistance and is commonly used in regions prone to hurricanes or strong winds.

3. Diagonal Pattern: Diagonal screw patterns involve placing screws at an angle across the panels. This pattern is useful for enhancing the roof’s ability to shed water quickly and is often used in areas with heavy rainfall.

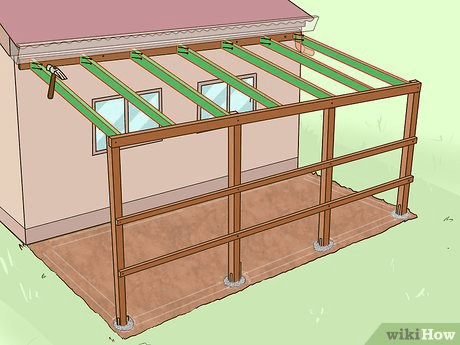

4. Batten Pattern: Batten patterns involve attaching metal battens or strips to the roof deck and then securing the metal panels to these battens. This method allows for greater airflow under the roof, reducing the risk of condensation.

Consult a Professional

Ultimately, the best screw pattern for your metal roof should be determined in consultation with a roofing professional. They will consider all the relevant factors, including your specific roof design and local climate conditions, to ensure a secure and long-lasting installation.

Conclusion

Choosing the right screw pattern for your metal roof is a crucial decision that should not be taken lightly. It impacts the roof’s performance, longevity, and ability to withstand adverse weather conditions. By considering factors such as roof slope, climate, panel type, fastener choice, and local building codes, you can make an informed choice and enjoy the many benefits of a well-installed metal roof.

Leave a Reply