Metal roofs are known for their durability and longevity, but proper installation is crucial to ensuring their effectiveness. One of the key factors in a successful metal roof installation is screw spacing. Correct screw spacing on metal roofs can significantly impact the roof’s performance and lifespan. In this comprehensive guide, we’ll cover everything you need to know about screw spacing on metal roofs, including why it’s important, how to determine the right spacing, and best practices for installation.

Why Screw Spacing Matters on Metal Roofs

Screw spacing on metal roofs is critical for several reasons:

- Structural Integrity: Proper screw spacing ensures that the metal panels are securely attached to the underlying structure. Incorrect spacing can lead to panel movement, which may result in leaks or damage.

- Weather Resistance: Adequate spacing helps prevent issues caused by extreme weather conditions, such as high winds and heavy snow loads. Properly spaced screws help maintain the roof’s ability to withstand these elements.

- Longevity: Correct screw placement helps extend the lifespan of the roof by reducing the risk of wear and tear on the panels and screws. Over time, improperly spaced screws can cause metal fatigue and premature roof failure.

- Aesthetic Appeal: Evenly spaced screws contribute to a neat and professional appearance. This is especially important for roofs that are visible from the ground or in high-profile locations.

Read too: How To Replace A Mobile Home Roof: Step-by-Step Guide for Homeowners

Determining the Right Screw Spacing for Your Metal Roof

The appropriate screw spacing for your metal roof depends on several factors, including the type of metal roof system, the roof pitch, and the local building codes. Here are some general guidelines to help you determine the right screw spacing:

1. Type of Metal Roof System

- Standing Seam Roofs: For standing seam metal roofs, screws are typically placed in the seams of the panels, where they are less visible and less likely to cause leaks. The spacing for these screws can vary depending on the manufacturer’s recommendations and the design of the roof.

- Corrugated Metal Roofs: For corrugated metal roofs, screws are usually placed in the high points of the corrugations. The spacing between screws is often determined by the gauge of the metal and the expected load.

- Metal Shingles: Metal shingles often require screws to be placed through the face of each shingle. The spacing may be influenced by the size of the shingles and the roofing manufacturer’s guidelines.

2. Roof Pitch

The pitch of the roof, or its angle, can affect the screw spacing. For roofs with a steep pitch, screws may need to be spaced closer together to account for the increased gravitational forces. Conversely, roofs with a low pitch may allow for wider spacing.

3. Local Building Codes

Local building codes and regulations can dictate the required screw spacing for metal roofs in your area. These codes take into account factors such as wind loads, snow loads, and seismic activity. Be sure to check with your local building department to ensure compliance with these codes.

Best Practices for Installing Screws on Metal Roofs

To ensure a successful installation, follow these best practices for screw spacing on metal roofs:

1. Follow Manufacturer’s Guidelines

Always refer to the manufacturer’s guidelines for screw spacing specific to your metal roof system. These guidelines provide the most accurate and reliable information for your particular roof type.

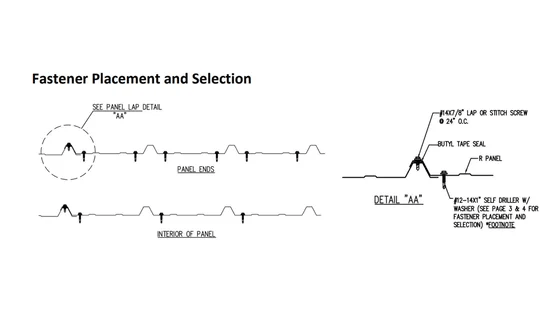

2. Use the Right Type of Screws

Select screws that are specifically designed for metal roofing. These screws typically feature a rubber washer to create a watertight seal and prevent leaks. Using the correct type of screws ensures proper attachment and longevity.

3. Pre-Drill Holes

In some cases, it may be beneficial to pre-drill holes in the metal panels to ensure accurate screw placement. This can help prevent misalignment and make the installation process smoother.

4. Avoid Over-Tightening

When installing screws, avoid over-tightening them, as this can strip the threads and compromise the seal. Tighten screws just enough to create a secure attachment without damaging the metal.

5. Check Alignment

Regularly check the alignment of the screws during installation to ensure they are consistently spaced and properly aligned. Misalignment can lead to structural issues and aesthetic concerns.

6. Inspect and Maintain

After installation, periodically inspect the screws and roof panels to ensure they remain secure. Address any issues promptly to prevent long-term damage.

Common Mistakes to Avoid

When dealing with screw spacing on metal roofs, avoid these common mistakes:

1. Ignoring Manufacturer Recommendations

Failing to follow the manufacturer’s recommendations for screw spacing can result in improper installation and potential issues with roof performance.

2. Using Incorrect Screw Types

Using the wrong type of screws or fasteners can lead to leaks, rust, and other problems. Always use screws designed for metal roofing applications.

3. Inconsistent Spacing

Inconsistent screw spacing can lead to weak points in the roof, which may result in damage or premature wear. Ensure that screws are evenly spaced according to the guidelines.

4. Neglecting Roof Pitch

Ignoring the roof pitch when determining screw spacing can lead to insufficient support and increased risk of damage. Adjust screw spacing based on the angle of the roof.

Benefits of Proper Screw Spacing

Proper screw spacing on metal roofs offers several benefits:

- Enhanced Durability: Correct spacing helps distribute loads evenly, reducing the risk of damage and extending the life of the roof.

- Improved Weather Resistance: Properly spaced screws help the roof withstand harsh weather conditions, such as strong winds and heavy rain.

- Reduced Maintenance Costs: A well-installed roof with correct screw spacing requires less maintenance and fewer repairs over time.

- Increased Property Value: A properly installed metal roof with correct screw spacing can enhance the overall value of your property.

Conclusion

Screw spacing on metal roofs is a critical factor in ensuring the structural integrity, weather resistance, and longevity of your roofing system. By understanding the importance of screw spacing and following best practices for installation, you can achieve a durable and reliable metal roof that will stand the test of time. Whether you are installing a new roof or maintaining an existing one, proper screw spacing is key to a successful and effective roofing solution.

Leave a Reply