Furring strips are an essential component of the installation process for metal roofs. These strips create a stable and level surface for the metal roofing panels to be attached to. Proper spacing of furring strips is crucial to ensure the integrity and longevity of the metal roof. In this article, we will delve into the significance of furring strips for metal roofs, the factors that influence their spacing, and the benefits of correct installation.

Understanding Furring Strips for Metal Roofs

What are Furring Strips for Metal Roofs?

Furring strips are narrow, long, and typically flat pieces of wood or metal that are placed horizontally across the roof’s surface. The purpose of furring strips is to create an even surface to which the metal roofing panels can be attached. They also provide additional support and ventilation for the roof, contributing to its overall performance and durability.

Importance of Proper Spacing

Why is Proper Spacing Important?

The spacing of furring strips plays a critical role in the structural integrity of the metal roof. Incorrect spacing can lead to various issues, such as:

- Panel Alignment: Properly spaced furring strips ensure that the metal roofing panels are aligned correctly. Misalignment can lead to gaps between panels, compromising the roof’s ability to keep out water and debris.

- Weight Distribution: Adequate spacing of furring strips distributes the weight of the metal roof evenly across the roof deck. This prevents undue stress on certain areas and helps maintain the roof’s stability.

- Ventilation: Proper spacing allows air circulation between the metal panels and the roof deck. This ventilation helps regulate temperature and prevents moisture buildup, reducing the risk of mold and rot.

- Thermal Expansion: Metal roofs expand and contract with temperature changes. The correct spacing accommodates this thermal movement without causing damage to the roofing system.

Factors Influencing Spacing

Factors to Consider for Furring Strip Spacing

Several factors come into play when determining the appropriate spacing for furring strips:

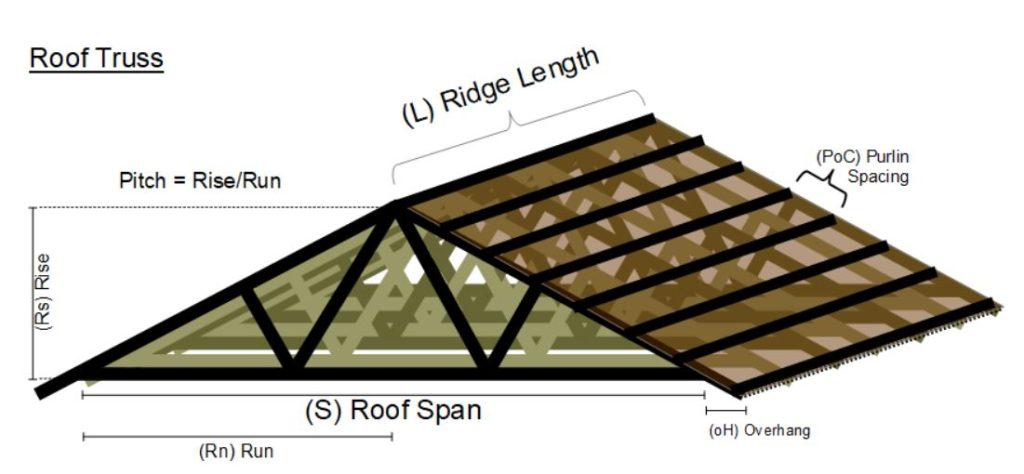

- Roof Pitch: The pitch or slope of the roof influences the spacing. Steeper roofs may require closer spacing to ensure proper support for the metal panels.

- Metal Panel Type: The type and gauge of the metal panels can affect the spacing of furring strips. Heavier panels may require closer spacing for additional support.

- Local Building Codes: Local building codes and regulations may specify minimum or maximum spacing requirements for furring strips.

- Roof Deck Material: The material of the roof deck (e.g., plywood, OSB) and its thickness can influence the spacing.

- Climate and Weather Conditions: Consider the climate and weather conditions of the area, including snow load and wind resistance, to determine appropriate spacing.

Benefits of Correct Furring Strip Installation

Advantages of Proper Furring Strip Installation

Properly installed furring strips offer several benefits:

- Enhanced Roof Lifespan: Ensuring correct spacing adequately supports and protects the metal roof, leading to a longer lifespan for the roofing system.

- Improved Roof Performance: Properly spaced furring strips contribute to the roof’s overall performance, including better ventilation, thermal regulation, and weight distribution.

- Code Compliance: Following recommended spacing guidelines ensures compliance with local building codes and regulations.

- Aesthetics: Proper alignment of metal roofing panels creates a visually appealing and uniform roof surface.

Conclusion

The correct spacing of furring strips is crucial for the successful installation and performance of a metal roof. Proper spacing ensures panel alignment, weight distribution, ventilation, and accommodates thermal expansion. Factors like roof pitch, metal panel type, local building codes, roof deck material, and climate influence the spacing decision. By following proper installation guidelines and spacing recommendations, homeowners and roofing professionals can ensure the longevity, stability, and durability of a metal roof, providing a reliable and visually pleasing roofing solution for years to come.

Leave a Reply