When considering a standing seam metal roof for your home or commercial building, one crucial aspect to understand is the minimum slope required for proper installation. The standing seam metal roof is renowned for its durability, sleek appearance, and resistance to weather. However, to ensure its effectiveness and longevity, adhering to the correct slope specifications is vital. This article will explore the importance of the standing seam metal roof slope minimum, how to determine it, and why it matters for your roofing project.

What is a Standing Seam Metal Roof?

Overview of Standing Seam Metal Roofs

A standing seam metal roof features raised seams or vertical strips that run the length of the roof, where panels are interlocked and fastened. This design helps create a watertight seal and offers several advantages:

- Durability: Resistant to severe weather conditions, including heavy rain and snow.

- Low Maintenance: Requires minimal upkeep compared to traditional roofing materials.

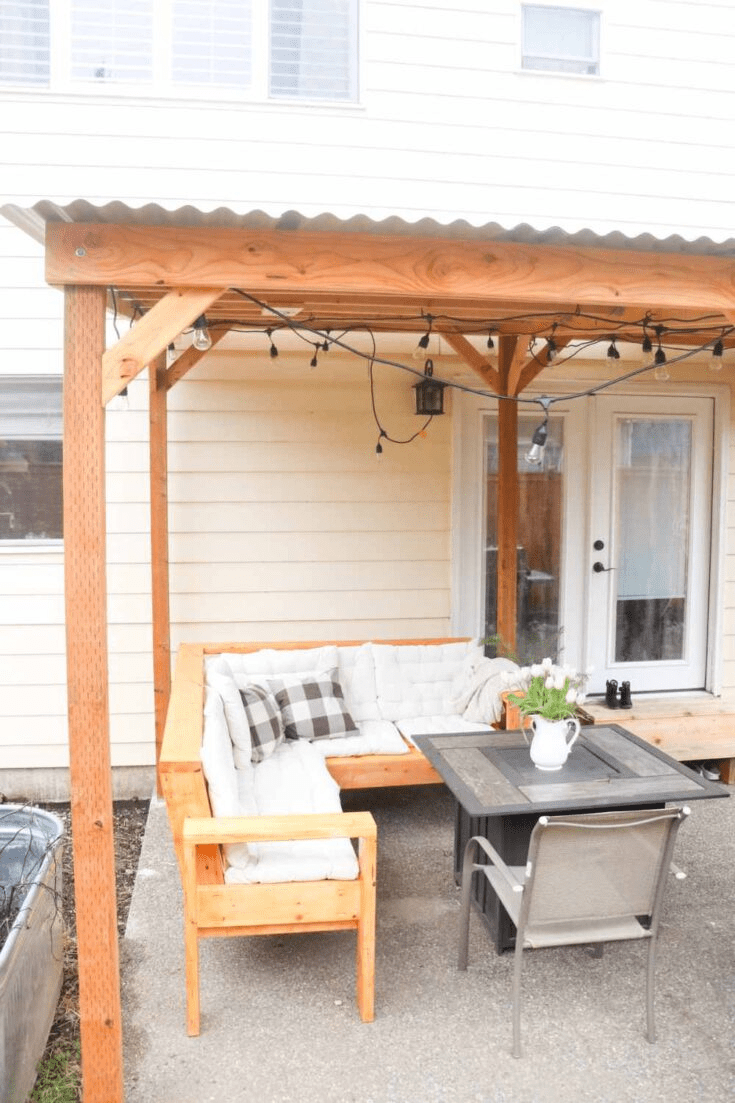

- Aesthetic Appeal: Offers a modern, clean look that enhances the building’s appearance.

Components of a Standing Seam Metal Roof

- Panels: The metal sheets or panels that cover the roof.

- Seams: Raised areas where panels are joined together.

- Fasteners: Secure the panels to the roof structure, often hidden from view.

Why is Roof Slope Important?

Understanding Roof Slope

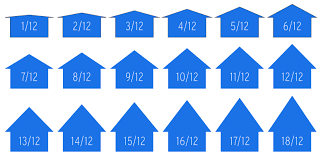

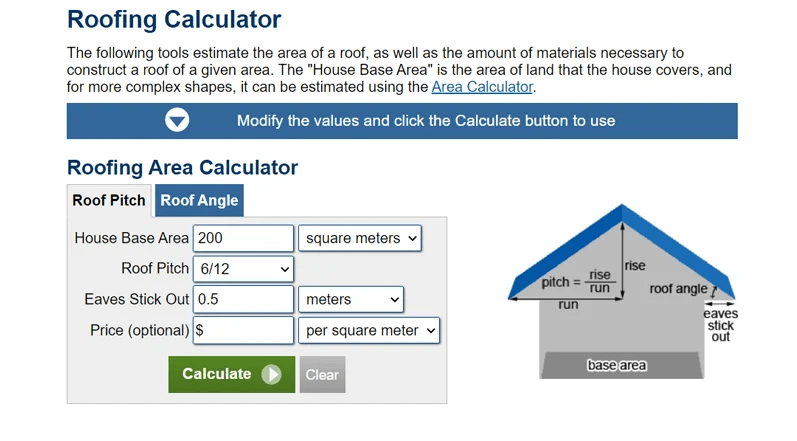

Roof slope, also known as pitch, refers to the angle or steepness of the roof. It is typically expressed as a ratio of vertical rise to horizontal run, such as 4:12, meaning the roof rises 4 inches for every 12 inches of horizontal run.

Read too: How To Replace A Mobile Home Roof: Step-by-Step Guide for Homeowners

Importance of Slope in Metal Roofing

- Water Drainage: A proper slope ensures that rainwater and snowmelt are effectively directed off the roof and away from the building.

- Preventing Leaks: Adequate slope reduces the risk of water pooling, which can lead to leaks and damage.

- Snow and Ice Management: A steeper slope helps prevent the buildup of snow and ice, reducing the risk of ice dams and associated problems.

Standing Seam Metal Roof Slope Minimum

Industry Standards

The minimum slope for standing seam metal roofs is crucial for ensuring optimal performance. Industry standards typically recommend a minimum slope of 3:12, which means the roof should rise at least 3 inches for every 12 inches of horizontal distance. However, this can vary depending on several factors:

- Manufacturer’s Specifications: Different metal roofing manufacturers may have specific requirements based on their products.

- Local Building Codes: Regional regulations may impose different slope requirements based on local weather conditions and building practices.

Why Adhere to Minimum Slope Requirements?

- Warranty Validity: Following the recommended slope ensures that you comply with manufacturer warranties and guarantees.

- Performance: A roof installed at the correct slope performs better in terms of water runoff and durability.

- Code Compliance: Meeting local building codes is essential for ensuring your roof is legally compliant and safe.

How to Determine the Appropriate Slope for Your Roof

Assessing Roof Design and Structure

- Roof Size and Complexity: Larger roofs or those with complex designs may require a steeper slope to ensure effective water drainage.

- Building Location: Areas with heavy snowfall or frequent rain may necessitate a steeper slope to handle increased water runoff.

Consulting with Professionals

- Roofing Contractors: Experienced roofing professionals can assess your specific situation and recommend the appropriate slope for your standing seam metal roof.

- Architects and Engineers: For complex roofing projects, consulting with architects or structural engineers can help ensure that the slope meets both aesthetic and functional requirements.

Installation Tips for Standing Seam Metal Roofs

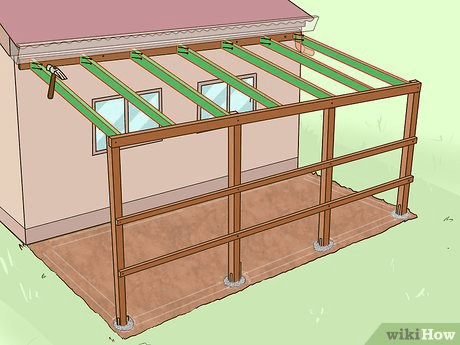

Preparing the Roof Deck

- Inspect the Deck: Ensure that the roof deck is clean, dry, and free of any debris or damage before installing the metal panels.

- Install Underlayment: A suitable underlayment should be installed to provide an additional layer of protection against moisture.

Panel Installation

- Align Panels Properly: Ensure that panels are aligned according to the specified slope and secured according to the manufacturer’s instructions.

- Seal Seams: Properly seal the seams to create a watertight barrier and prevent leaks.

Regular Maintenance

- Inspect Periodically: Regularly check the roof for any signs of damage or wear, especially after severe weather events.

- Clean the Roof: Remove debris and check for any issues that may affect the performance of the roof.

Conclusion

Understanding the minimum slope for standing seam metal roofs is essential for ensuring that your roof performs optimally and remains durable over time. Adhering to industry standards and manufacturer recommendations helps protect your investment and ensures that your roof provides effective protection against the elements. By consulting with professionals and carefully planning your roofing project, you can achieve a successful installation that meets all necessary requirements.

Leave a Reply