When it comes to commercial roofing, TPO (Thermoplastic Polyolefin) roofing has gained significant popularity in recent years. TPO roofing offers a cost-effective and durable solution for flat roofs, making it a preferred choice for many property owners. However, to ensure a successful TPO roofing installation, one critical factor to consider is the temperature during the installation process. In this article, we will explore the importance of the TPO roofing installation temperature and its impact on the overall roofing project.

Understanding TPO Roofing

TPO Roofing: An Overview

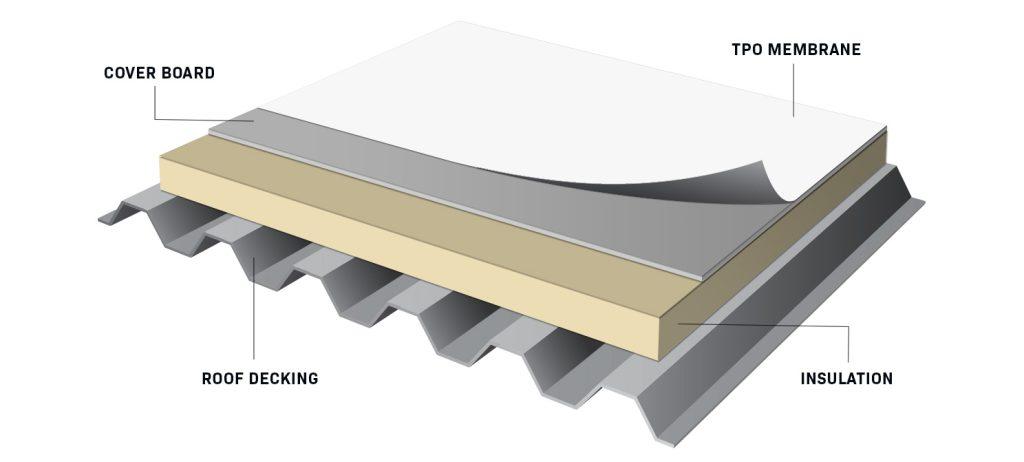

TPO roofing is a single-ply roofing membrane that consists of a blend of polypropylene and ethylene-propylene rubber. This combination gives TPO roofing excellent flexibility, durability, and resistance to UV rays and weathering. It comes in large rolls, which are then heat-welded together during installation to create a seamless and watertight roofing surface.

Advantages of TPO Roofing

TPO roofing offers several advantages that have contributed to its rising popularity in the commercial roofing industry. Some of these benefits include:

- Cost-Effective: TPO roofing is relatively more affordable compared to other commercial roofing options, making it an attractive choice for budget-conscious property owners.

- Energy Efficiency: TPO roofing is available in light colors that reflect sunlight, reducing heat absorption and helping to keep the building cooler, thus enhancing energy efficiency.

- Durability: TPO roofing is highly resistant to tears, impacts, and punctures, ensuring a long-lasting and low-maintenance roofing solution.

- Environmentally Friendly: TPO roofing is recyclable, making it an eco-friendly roofing option for those concerned about sustainability.

- Easy Installation: The large rolls and heat-welding installation method make TPO roofing installations relatively quick and efficient.

The Impact of Temperature on TPO Roofing Installation

The Ideal TPO Roofing Installation Temperature

Temperature plays a crucial role during TPO roofing installation. The ideal temperature range for installing TPO roofing is typically between 40°F (4°C) to 100°F (38°C). Within this range, the TPO membrane is more pliable, making it easier to handle during installation. In colder temperatures, the TPO membrane may become stiff and difficult to work with, while in hotter temperatures, the membrane might become too soft and prone to damage.

Cold Weather Installation

Installing TPO roofing in extremely cold weather can be challenging. The material becomes less flexible, making it harder to weld the seams properly. Inadequate seam welding can lead to water infiltration, which can cause leaks and compromise the roof’s integrity. Additionally, cold weather can affect the adhesive properties of the bonding agents used during installation, further compromising the roof’s performance.

Hot Weather Installation

Similar challenges arise when installing TPO roofing in hot weather. The extreme heat can cause the membrane to become excessively soft, making it more susceptible to cuts and punctures during handling. Moreover, the heat can lead to premature curing of adhesives, reducing their effectiveness in creating strong bonds.

Tips for Successful TPO Roofing Installation

1. Plan the Installation According to Temperature: It is essential to check the weather forecast and plan the TPO roofing installation during a period when temperatures fall within the recommended range.

2. Use Proper Heating Equipment: In colder temperatures, using heating equipment, such as a hot air welder, can help soften the TPO membrane, making it more workable.

3. Store Materials Appropriately: Store TPO rolls in a shaded area during hot weather to prevent overheating and keep them warm in cold weather to maintain flexibility.

4. Work with Experienced Roofing Contractors: Hiring experienced roofing contractors who are familiar with TPO roofing installation techniques and temperature considerations is crucial for a successful project.

Conclusion

In conclusion, TPO roofing installation temperature is a critical factor that can significantly impact the success and longevity of the roofing project. Property owners and roofing contractors must pay close attention to temperature conditions during installation to ensure the TPO membrane’s proper handling and welding. By adhering to the recommended temperature range and following best practices, TPO roofing can provide exceptional performance, durability, and energy efficiency, making it an excellent choice for commercial roofing applications.

Leave a Reply