EPDM (Ethylene Propylene Diene Monomer) roofing is a popular choice for flat and low-slope roofs due to its durability, cost-effectiveness, and ease of installation. If you’re considering tackling a roofing project yourself, learning How To Install EPDM Roofing can save you a significant amount of money while providing a long-lasting roofing solution. In this guide, we’ll walk you through the process of installing EPDM roofing, ensuring that you have all the information you need to complete the job successfully.

Understanding EPDM Roofing

What is EPDM Roofing?

EPDM is a type of synthetic rubber roofing membrane that is widely used in both residential and commercial roofing applications. It is known for its excellent resistance to UV radiation, ozone, and weathering, making it an ideal choice for a variety of climates. EPDM roofing is available in a range of thicknesses, with the most common being 45 mils and 60 mils. It also comes in two colors: black and white, with white EPDM offering additional reflectivity, which can help reduce cooling costs.

Read too: How To Replace Roof Shingles That Blew Off: A Comprehensive Guide

Benefits of EPDM Roofing

Before diving into How To Install EPDM Roofing, it’s essential to understand why this material is a popular choice. Some of the key benefits include:

- Durability: EPDM roofing can last up to 50 years with proper maintenance, making it one of the longest-lasting roofing options available.

- Cost-Effective: Compared to other roofing materials, EPDM is relatively inexpensive, especially when considering its longevity.

- Easy Installation: EPDM is lightweight and can be installed with minimal tools, making it an ideal choice for DIY projects.

- Energy Efficiency: White EPDM reflects sunlight, reducing the amount of heat absorbed by the roof, which can lower cooling costs in hot climates.

- Environmentally Friendly: EPDM is made from recycled materials and is 100% recyclable at the end of its life, making it an eco-friendly roofing option.

Tools and Materials Needed for EPDM Roofing Installation

Before you begin the installation process, you’ll need to gather the necessary tools and materials. Here’s a list to get you started:

Tools:

- Utility knife or scissors

- Measuring tape

- Chalk line

- Roller

- Broom or leaf blower

- Paintbrushes (for applying adhesive)

- Ladder

- Safety gear (gloves, safety glasses, etc.)

Materials:

- EPDM roofing membrane (ensure you have enough to cover the entire roof area)

- EPDM adhesive (water-based or solvent-based, depending on your preference)

- EPDM seam tape (for sealing the seams between membrane sheets)

- Termination bar or edge flashing (to secure the edges of the membrane)

- EPDM primer (for preparing the surface before applying the seam tape)

- EPDM cover tape (for reinforcing seams and flashings)

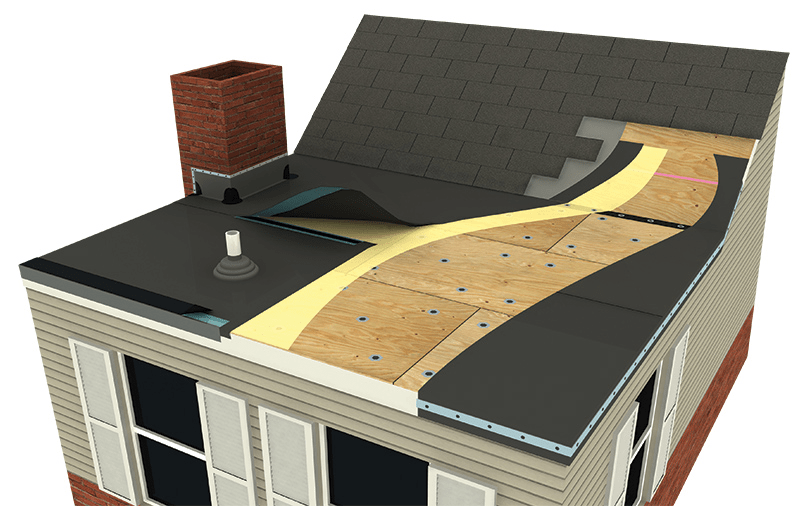

Preparing the Roof Surface

Inspect and Clean the Roof

Before installing the EPDM membrane, it’s crucial to prepare the roof surface properly. Start by inspecting the roof for any damage, such as cracks, holes, or loose materials. Any existing issues should be repaired before proceeding with the installation.

Once the roof is in good condition, clean the surface thoroughly. Use a broom or leaf blower to remove any dirt, debris, and loose particles. A clean surface is essential for ensuring that the adhesive bonds properly to the roof.

Measuring and Cutting the Membrane

Accurate measurements are critical when installing EPDM roofing. Measure the dimensions of your roof and cut the EPDM membrane to fit, leaving an extra 6-12 inches on each side for overhang. This overhang will be trimmed after the membrane is fully adhered to the roof.

To ensure the membrane lays flat and without wrinkles, it’s advisable to lay it out on the roof for a few hours before installation. This allows the material to relax and makes it easier to handle during the installation process.

How To Install EPDM Roofing: Step-by-Step Guide

Step 1: Apply the Adhesive

With your membrane cut and ready, it’s time to apply the adhesive. Start by folding back half of the membrane, exposing the roof surface beneath. Using a paintbrush or roller, apply a thin, even layer of adhesive to both the roof surface and the underside of the membrane. Be sure to follow the manufacturer’s instructions regarding adhesive coverage and drying time.

Once the adhesive has become tacky (but not dry), carefully roll the membrane back into place, pressing it down firmly to ensure a strong bond. Use a roller to smooth out any air bubbles or wrinkles, working from the center outward to the edges.

Step 2: Secure the Seams

After the first half of the membrane is adhered to the roof, repeat the process on the other half. Once the entire membrane is in place, it’s time to secure the seams between the sheets.

Apply EPDM primer along the seam where the two membrane sheets meet. After the primer has dried, apply EPDM seam tape along the seam, ensuring it’s centered over the joint. Use a roller to press the seam tape firmly into place, removing any air bubbles and ensuring a watertight seal.

Step 3: Trim the Excess Membrane

With the membrane fully adhered and the seams secured, you can now trim the excess material from the edges. Use a utility knife or scissors to carefully cut the overhang, leaving about 1-2 inches of membrane extending past the edge of the roof.

Step 4: Install Edge Flashing or Termination Bar

To secure the edges of the membrane and prevent water infiltration, install edge flashing or a termination bar along the roof perimeter. This step is crucial for ensuring the longevity and performance of your EPDM roof.

Attach the flashing or termination bar to the roof edge using appropriate fasteners, making sure it’s securely anchored. Once installed, apply a bead of EPDM sealant along the top edge of the flashing or termination bar to create a watertight seal.

Step 5: Inspect and Finish

After completing the installation, take the time to inspect the entire roof, checking for any areas that may require additional attention. Look for air bubbles, wrinkles, or loose seams, and address these issues immediately to prevent future problems.

Once you’re satisfied with the installation, allow the adhesive to cure fully, which may take several days depending on the weather conditions. During this time, avoid walking on the roof to prevent damaging the membrane.

Maintenance Tips for EPDM Roofing

Regular Inspections

To ensure the longevity of your EPDM roof, it’s important to conduct regular inspections. Check the roof for signs of damage, such as cracks, tears, or loose seams, and address any issues promptly. Regular inspections can help you catch minor problems before they turn into major repairs.

Cleaning the Roof

EPDM roofs are relatively low maintenance, but occasional cleaning is necessary to keep them in good condition. Use a soft-bristle broom or a leaf blower to remove debris, and if necessary, wash the roof with a mild detergent and water solution. Avoid using harsh chemicals or abrasive tools, as these can damage the membrane.

Repairing Damage

If you notice any damage to your EPDM roof, such as a puncture or tear, it’s important to repair it as soon as possible to prevent leaks. EPDM repair kits are available and typically include patches, adhesive, and primer. Follow the manufacturer’s instructions to ensure a proper repair.

Advantages of DIY EPDM Roofing Installation

Cost Savings

One of the biggest advantages of installing EPDM roofing yourself is the cost savings. By handling the installation yourself, you can avoid the labor costs associated with hiring a professional contractor. Additionally, EPDM roofing materials are relatively affordable, making this a budget-friendly option for homeowners.

Customization and Control

DIY installation gives you full control over the project, allowing you to customize the roof to meet your specific needs. Whether you’re working on a small shed or a large commercial building, you can tailor the installation process to suit the unique requirements of your project.

Learning Experience

For those who enjoy hands-on projects, installing EPDM roofing can be a rewarding learning experience. Not only will you gain valuable skills and knowledge, but you’ll also have the satisfaction of completing a major home improvement project on your own.

When to Consider Professional Installation

Complex Roof Designs

While DIY EPDM roofing installation is feasible for many homeowners, there are certain situations where it may be best to hire a professional. If your roof has a complex design, multiple penetrations (such as vents or chimneys), or steep slopes, professional installation may be necessary to ensure a proper fit and seal.

Time Constraints

Installing EPDM roofing can be time-consuming, especially if you’re new to the process. If you’re working under a tight deadline or simply don’t have the time to devote to the project, hiring a professional contractor can ensure the job is completed efficiently and correctly.

Peace of Mind

For homeowners who prefer to leave major projects to the experts, professional installation offers peace of mind. Professional contractors have the experience and tools necessary to complete the job to a high standard, reducing the risk of issues down the line.

Conclusion

Learning How To Install EPDM Roofing can be a valuable skill for any DIY enthusiast. With its durability, cost-effectiveness, and ease of installation, EPDM roofing is an excellent choice for flat and low-slope roofs. By following the steps outlined in this guide, you can confidently tackle your EPDM roofing project, ensuring a long-lasting, watertight roof that will protect your home for years to come.

Leave a Reply