Metal roofing is a popular choice for homeowners and builders alike, thanks to its durability, energy efficiency, and modern appearance. But one key question often arises during installation: Does metal roof need underlayment? The short answer is yes, but the reasons behind it are important to understand for anyone planning to install a metal roof. In this comprehensive article, we’ll explore why underlayment is essential for metal roofing, the different types of underlayment available, and how to choose the best option for your home or building.

What is Roof Underlayment?

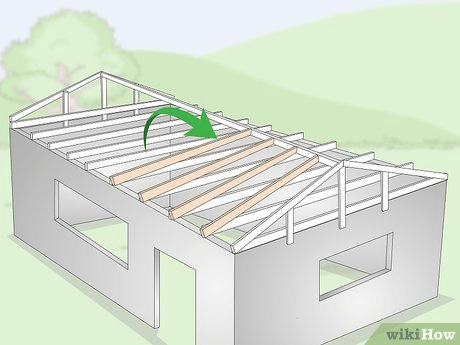

Roof underlayment is a protective layer that goes between your roof deck (usually made of plywood or oriented strand board, OSB) and the metal roof panels. Its primary role is to act as a secondary barrier against moisture, providing extra protection in case water penetrates the roof’s outer surface. Underlayment can also add insulation, help prevent condensation, and provide a smoother surface for installing the metal roof panels.

Read too: How To Replace Roof Shingles That Blew Off: A Comprehensive Guide

Does Metal Roof Need Underlayment?

Why is Underlayment Necessary for Metal Roofs?

While metal roofing is highly resistant to the elements, it is not immune to issues such as water infiltration, condensation, and temperature fluctuations. Here’s why metal roofs need underlayment:

- Moisture Protection: Even though metal roofs are excellent at shedding water, leaks can still occur due to improperly installed fasteners, flashings, or seams. Underlayment provides an extra layer of water resistance, helping to prevent moisture from reaching the roof deck and causing rot or structural damage.

- Condensation Prevention: Metal roofs can sometimes experience condensation, especially in areas with extreme temperature changes. Without proper underlayment, condensation can drip onto the roof deck and lead to mold growth, wood rot, or other moisture-related issues.

- Improved Energy Efficiency: Some types of underlayment can help enhance the insulation of your roof. This is especially important in regions that experience high temperatures, as the underlayment can reduce heat transfer from the metal roof to the interior of the home.

- Smooth Installation Surface: Metal roofing panels require a smooth surface for proper installation. Roof underlayment helps ensure that the panels lay evenly and don’t warp or shift over time, which could cause issues with weather resistance.

Types of Underlayment for Metal Roofs

There are several types of underlayment to consider when installing a metal roof. Each type has its own advantages and disadvantages depending on factors like your climate, the roof’s design, and your budget. Below are the most common types:

1. Felt Underlayment

Felt underlayment, also known as “tar paper,” is a traditional option made from a combination of asphalt and either organic or fiberglass matting. It has been widely used in roofing for decades, and it’s typically the most affordable option.

- Pros: Felt underlayment is relatively inexpensive and provides basic protection against moisture.

- Cons: Felt is less durable than synthetic options and can tear or wrinkle during installation. It’s also not as effective in extreme weather conditions like heavy rain or high heat.

2. Synthetic Underlayment

Synthetic underlayment is made from various types of plastics and polymers, making it stronger and more durable than traditional felt. It has become increasingly popular in modern roofing due to its superior performance.

- Pros: Synthetic underlayment is lightweight, tear-resistant, and highly durable. It offers better moisture protection than felt and can withstand higher temperatures without breaking down. Synthetic options also tend to have a longer lifespan.

- Cons: Synthetic underlayment is more expensive than felt, which may be a drawback for budget-conscious homeowners.

3. Self-Adhering Membrane

Self-adhering membrane underlayment is a specialized type of underlayment that is commonly used in areas prone to ice dams, heavy rain, or extreme weather conditions. This underlayment has an adhesive backing, which allows it to stick directly to the roof deck, providing a watertight seal.

- Pros: Self-adhering membranes offer superior moisture protection and are highly effective in preventing ice dams and leaks caused by extreme weather. They are also durable and long-lasting.

- Cons: This type of underlayment is the most expensive option and can be difficult to install. It is typically used only in specific situations where extreme weather protection is necessary.

Does Metal Roof Need Underlayment in All Climates?

The need for underlayment can vary depending on your local climate and the specific requirements of your building. Here’s how climate plays a role in deciding whether metal roofs need underlayment:

1. Hot Climates

In areas with hot, sunny weather, underlayment is essential for preventing heat from penetrating through the roof and into the home. Metal roofs can absorb a lot of heat from the sun, and underlayment helps to create a thermal barrier, making the home more energy-efficient and reducing cooling costs.

2. Cold Climates

In colder regions, underlayment plays a crucial role in preventing ice dams and condensation. When snow or ice melts on the metal roof, underlayment can help prevent water from leaking into the roof deck. It also acts as a vapor barrier, reducing the chance of moisture buildup due to condensation.

3. Wet or Humid Climates

In areas with heavy rain or high humidity, underlayment is necessary to protect the roof deck from water damage. Even small leaks can lead to major structural problems if the moisture is allowed to seep into the wood. Underlayment provides a secondary layer of moisture protection, helping to safeguard the home from rot and mold growth.

Installation Tips for Metal Roof Underlayment

If you’ve determined that your metal roof needs underlayment, here are some best practices to ensure a successful installation:

1. Choose the Right Type of Underlayment

As discussed earlier, selecting the right type of underlayment depends on your climate, roof design, and budget. If you’re in an area prone to extreme weather conditions, synthetic or self-adhering underlayment may be the best choice.

2. Ensure Proper Overlap

When installing underlayment, it’s important to overlap each layer to create a continuous barrier against moisture. A standard overlap of 4-6 inches is recommended to prevent water from seeping through the seams.

3. Secure the Underlayment with the Correct Fasteners

For best results, use roofing nails or staples specifically designed for underlayment. Be sure to follow the manufacturer’s guidelines for fastener placement to avoid any gaps or wrinkles in the material.

4. Seal Around Roof Penetrations

Areas where pipes, vents, or chimneys penetrate the roof are particularly vulnerable to leaks. Make sure to seal the underlayment tightly around these areas using adhesive or flashing to prevent water from infiltrating the roof.

5. Work with a Professional Roofer

While some homeowners may attempt to install underlayment on their own, working with a professional roofer ensures that the job is done correctly and safely. A licensed contractor will have the experience and expertise needed to select and install the appropriate underlayment for your roof.

Frequently Asked Questions About Metal Roof Underlayment

1. Can I Install a Metal Roof Without Underlayment?

While it is technically possible to install a metal roof without underlayment, it’s not recommended. The underlayment provides important protection against moisture, heat, and other potential issues. Skipping this step can lead to long-term damage to your roof deck, reducing the lifespan of your roof.

2. How Much Does Underlayment Add to the Cost of a Metal Roof?

The cost of underlayment depends on the type you choose. Felt underlayment is the least expensive option, typically ranging from $0.10 to $0.50 per square foot. Synthetic underlayment is more expensive, costing between $0.50 and $1.00 per square foot. Self-adhering membrane is the most costly, ranging from $1.00 to $2.00 per square foot. However, the additional cost is worth the investment in the long-term performance and durability of your roof.

3. How Long Does Underlayment Last Under a Metal Roof?

The lifespan of underlayment depends on the type you select and your local climate. Synthetic and self-adhering membranes typically last longer than felt, with some synthetic options lasting up to 30 years. However, since metal roofs themselves can last 40-70 years, it’s important to choose an underlayment that will provide adequate protection over the long term.

4. What Happens If Underlayment Gets Wet During Installation?

It’s not uncommon for underlayment to get wet during the installation process, especially if you’re working in a rainy climate. Most types of underlayment are designed to handle some exposure to moisture, but it’s important to ensure that the material dries out before installing the metal roofing panels.

Conclusion: Does Metal Roof Need Underlayment?

To answer the question Does metal roof need underlayment?—yes, underlayment is a crucial part of any metal roof installation. It offers multiple benefits, including moisture protection, improved energy efficiency, and enhanced durability. Whether you’re installing a metal roof in a hot, cold, or wet climate, underlayment is essential to ensure the longevity and performance of your roof. Be sure to choose the right type of underlayment based on your needs, and consider working with a professional roofer for the best results.

Leave a Reply