For businesses that rely on box trucks for transportation and delivery, maintaining the integrity of the vehicle is crucial. The roof of a box truck is susceptible to damage over time due to weather conditions, accidents, or wear and tear. When it comes to box truck roof repair, understanding the potential costs involved is essential. In this article, we will explore the factors that contribute to box truck roof repair cost and provide insights to help businesses plan for these expenses.

Assessing the Extent of Roof Damage

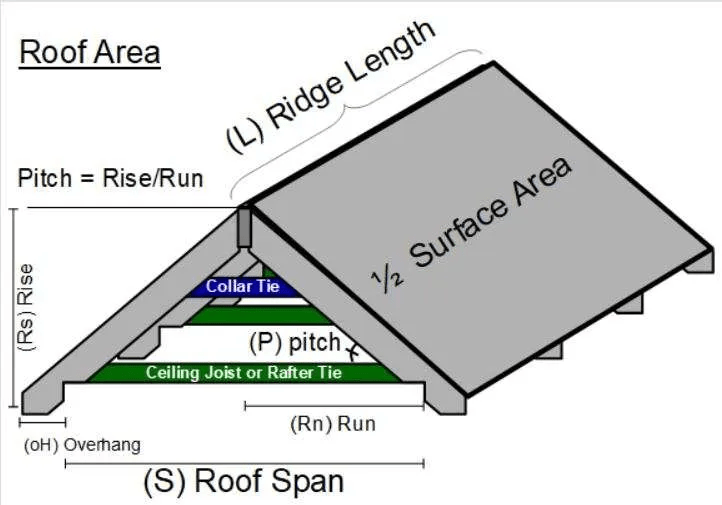

The first step in determining the repair cost is to assess the extent of the roof damage. This can range from minor issues like leaks or small punctures to more severe damage requiring extensive repairs or even roof replacement. Conduct a thorough inspection of the roof, looking for signs of water damage, cracks, holes, or loose seams. The severity and extent of the damage will directly impact the repair cost.

Material and Labor Costs

The choice of materials for box truck roof repair and the associated labor costs play a significant role in determining the overall expenses. The type of roof material, such as aluminum, fiberglass, or rubber, will affect the cost of materials. Additionally, the complexity of the repair, the required equipment, and the expertise of the repair technicians will influence the labor costs. Obtaining multiple quotes from reputable repair service providers will help in assessing the material and labor expenses accurately.

Structural Considerations and Modifications

In some cases, roof damage may require structural repairs or modifications. This can include reinforcing the roof structure, replacing damaged support beams, or making adjustments to improve the overall strength and stability of the roof. These additional structural considerations will impact the repair cost and should be taken into account during the estimation process.

Prevention of Future Damage

While addressing the current roof damage is essential, it is also important to consider preventive measures to minimize future issues. This can include applying coatings or sealants to protect the roof from further damage, installing additional reinforcement or protective measures, or implementing regular maintenance routines. Although these preventive steps may incur additional costs upfront, they can save businesses money in the long run by reducing the need for frequent repairs.

Conclusion:

Box truck roof repair costs can vary depending on the extent of the damage, materials used, labor fees, and any necessary structural modifications. By assessing the roof damage, obtaining multiple quotes, and considering preventive measures, businesses can plan and budget for box truck roof repairs effectively. Regular maintenance and prompt repairs can help prolong the lifespan of the roof, ensuring the reliability and functionality of box trucks in transportation and delivery operations.

Leave a Reply