Installing a metal roof is a significant investment in your home’s protection and aesthetic appeal. One critical aspect of a successful metal roof installation is understanding how much overlap on metal roofing is needed. The overlap is the key to creating a watertight seal, ensuring your roof can withstand the elements for years to come. In this guide, we will explore the importance of overlap in metal roofing and provide you with essential tips for a secure and durable installation.

Understanding

Why Overlap Matters

The overlap in metal roofing plays a crucial role in preventing water infiltration. Rain, snow, and moisture are the primary adversaries of your roof. Proper overlap ensures that water is directed away from vulnerable areas like seams and fasteners, keeping your home dry and free from water damage.

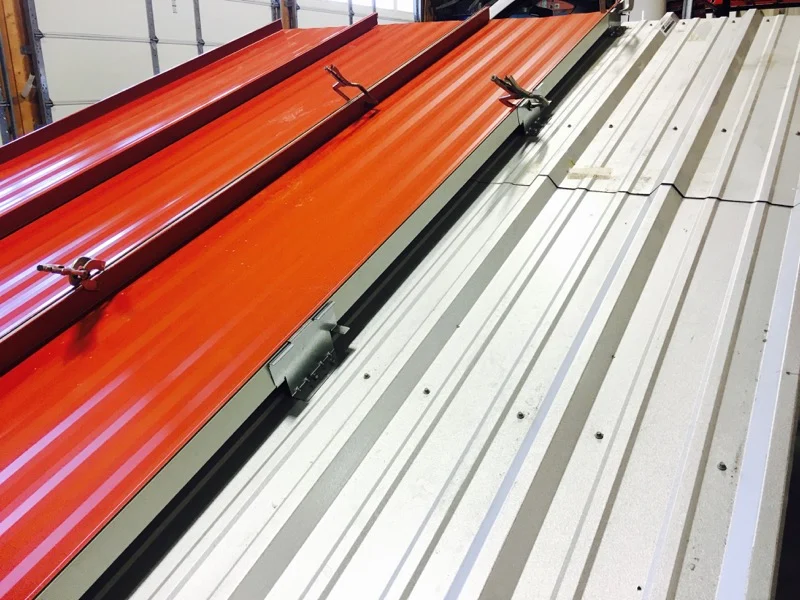

Types of Metal Roofing Overlap

There are two common types of overlap in metal roofing:

- End Lap: This is the overlap that occurs at the end of two metal panels. It is typically recommended to have a minimum end lap of 6 inches, although specific requirements may vary depending on the manufacturer and local building codes.

- Side Lap: Side lap is the overlap that occurs along the length of two adjacent metal panels. The recommended side lap can range from 1 inch to 3 inches, again depending on the manufacturer’s specifications and local building codes.

Factors Affecting Overlap

Several factors can influence the required overlap on metal roofing:

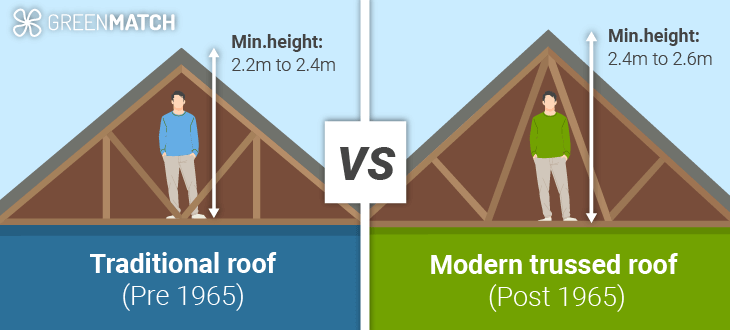

- Roof Pitch: Steeper roofs may require a larger overlap to ensure proper water shedding.

- Local Climate: Areas with heavy rainfall or snowfall may require a larger overlap to handle increased water volume.

- Metal Gauge: Thicker metal panels may allow for smaller overlaps due to their increased strength and durability.

- Manufacturer’s Recommendations: Always refer to the manufacturer’s guidelines for specific overlap requirements for your chosen metal roofing product.

Installation Tips for Proper Overlap

Follow Manufacturer Instructions

Before starting your metal roof installation, carefully read and follow the manufacturer’s instructions regarding overlap requirements. Different types of metal roofing may have unique specifications, so it’s essential to use the recommended overlap for your specific product.

Use Proper Fasteners

In addition to overlap, the type and placement of fasteners are critical. Use the recommended fasteners and ensure they are correctly positioned according to the manufacturer’s guidelines. Properly secured fasteners contribute to the overall integrity of your metal roof.

Inspect and Maintain Regularly

Even with a correctly installed metal roof, regular inspections are crucial to identify any potential issues, such as loose fasteners or damaged panels. Address any problems promptly to prevent water infiltration.

Conclusion: Protecting Your Home with Proper Overlap

Understanding how much overlap on metal roofing is required is essential for a successful installation. It’s a critical factor in ensuring your roof’s longevity and its ability to protect your home from the elements. By following manufacturer guidelines, considering local factors, and using proper installation techniques, you can enjoy the benefits of a durable and watertight metal roof for years to come. Proper overlap is not just a technical detail; it’s your home’s first line of defense against the weather.

Leave a Reply