Oil canning metal roof is a common concern for homeowners and contractors working with metal roofing systems. While metal roofs are praised for their durability, energy efficiency, and longevity, the phenomenon of oil canning can cause both aesthetic and structural issues if not addressed properly. In this article, we will dive into what oil canning is, why it occurs, how to prevent it, and what can be done to remedy it.

What is Oil Canning on Metal Roofs?

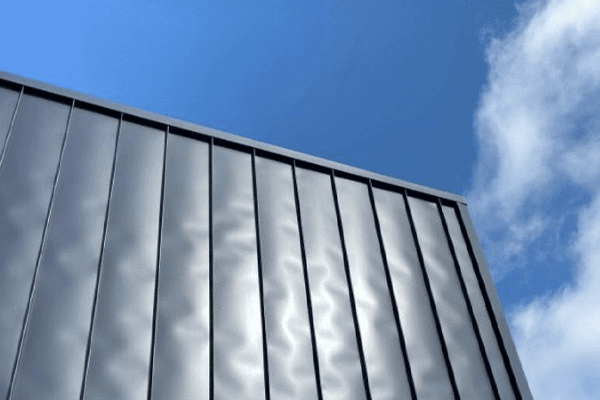

Oil canning, also known as “elastic buckling” or “stress wrinkling,” refers to the visible waviness or distortion that occurs in the flat sections of metal roofing panels. This visual imperfection is most commonly seen on standing seam metal roofs, but it can also affect metal siding and other types of metal panels.

The term “oil canning” originated in the days when people used oil cans made of thin sheet metal. Pressing the sides of the can would cause it to bend or pop, producing a wave-like deformation. A similar effect occurs with thin metal roofing panels when they expand and contract due to thermal stress or are improperly installed.

Read too: How To Replace A Mobile Home Roof: Step-by-Step Guide for Homeowners

Causes of Oil Canning in Metal Roofs

1. Thermal Expansion and Contraction

Metal naturally expands and contracts with temperature changes. When a metal roof is exposed to heat, the material expands, and as it cools down, it contracts. This continuous cycle of expansion and contraction can cause the metal to buckle or create visible waves if the panels were not installed with sufficient room to accommodate these movements.

2. Improper Panel Installation

A key factor contributing to oil canning metal roof issues is improper installation. If the metal roofing panels are installed too tightly or with uneven pressure, they won’t have the flexibility to adjust to temperature fluctuations. Even the smallest misalignment can create tension within the panel, causing it to bend and buckle over time.

3. Inadequate Substructure Support

The substructure, or the framing beneath the metal panels, plays a vital role in maintaining the stability of the roof. If the substructure is uneven or lacks proper support, it can increase the likelihood of oil canning. The panels rely on the substructure to remain flat and stable. An inconsistent or poorly constructed substructure will lead to visible waviness in the metal panels.

4. Improper Metal Gauge Selection

The thickness (gauge) of the metal plays a significant role in its resistance to oil canning. Thinner metal panels are more prone to oil canning because they have less structural integrity and are more susceptible to buckling under stress. On the other hand, thicker panels are more rigid and less likely to show signs of waviness. Choosing the correct metal gauge for your roof is crucial in minimizing the risk of oil canning.

5. Manufacturing Defects or Stress

During the manufacturing process, the metal panels can undergo stress from rolling, cutting, or forming, which can lead to oil canning. If the metal is mishandled or overly stressed during the manufacturing process, it can develop imperfections before even being installed on your roof. Choosing a reputable manufacturer and supplier is essential to ensure the quality of the material.

How to Prevent Oil Canning on Metal Roofs

1. Choose the Right Gauge

One of the most effective ways to prevent oil canning metal roof issues is by selecting the appropriate metal gauge for your project. As a general rule, thicker panels (lower gauge numbers) are less prone to oil canning due to their rigidity and structural integrity. It’s essential to work with a roofing professional to determine the best gauge for your specific application, taking into account the local climate, the roof’s exposure to direct sunlight, and the overall design of the roof.

2. Proper Installation Techniques

Installation plays a critical role in preventing oil canning. Panels should be installed with the correct amount of tension and spacing to allow for natural expansion and contraction. It’s also important to avoid over-tightening the fasteners, as this can create excessive tension within the panels.

Roofing professionals should follow manufacturer guidelines carefully to ensure proper spacing between fasteners, the right method of attaching the panels, and the use of expansion joints where necessary. These techniques help maintain the flexibility of the panels, reducing the risk of oil canning.

3. Use Stiffening Ribs or Striations

Another method to prevent oil canning is to add stiffening ribs, also known as striations, to the flat sections of the metal panels. These small ridges or indentations help distribute stress more evenly across the panel, reducing the likelihood of waviness. While striations can slightly alter the appearance of the panels, they provide additional strength and resistance to oil canning without compromising the aesthetic appeal.

4. Ensure a Solid and Even Substructure

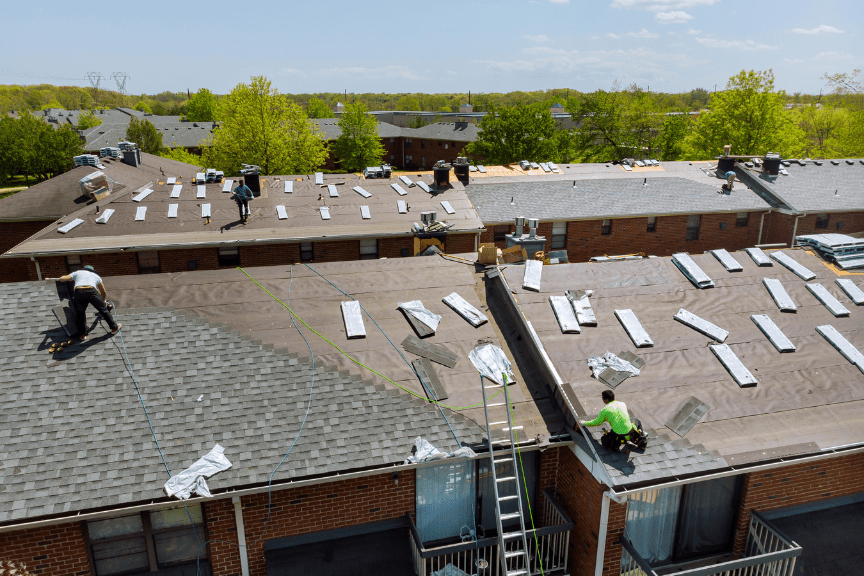

A flat, stable, and well-supported substructure is critical to preventing oil canning. Before installing the metal roof panels, it’s essential to ensure that the underlying structure is level and free of defects. If there are any issues with the substructure, such as uneven surfaces or inadequate support, they should be addressed before the metal panels are installed.

Contractors should use high-quality materials for the substructure and ensure that it is securely fastened to the roof deck. This provides a stable foundation for the metal panels, reducing the chances of oil canning.

5. Select a High-Quality Manufacturer

Working with a reputable manufacturer is another important step in preventing oil canning. High-quality metal panels are less likely to have defects or stress points that can lead to buckling. Additionally, a good manufacturer will provide detailed installation instructions and support, ensuring that the panels are installed correctly and are less prone to oil canning.

How to Fix Oil Canning on Metal Roofs

1. Reinstall or Adjust the Panels

In cases where oil canning is caused by improper installation, one solution is to reinstall or adjust the panels to relieve the tension that caused the waviness. A professional roofing contractor can assess the situation and determine whether loosening the fasteners, repositioning the panels, or adding expansion joints can help reduce the appearance of oil canning.

2. Add Reinforcement

If the panels are too thin or lack the necessary structural support, adding additional reinforcement may help. This can involve installing additional stiffening ribs, increasing the thickness of the panels, or adding support to the substructure. These reinforcements can improve the rigidity of the panels, helping to minimize oil canning.

3. Replace the Affected Panels

In some cases, the only solution may be to replace the affected panels with thicker or higher-quality metal. If the original panels were too thin or defective, installing new panels that are better suited for the environment and installation conditions can resolve the issue.

4. Use Professional Help

Since oil canning is often linked to installation and manufacturing techniques, it’s crucial to work with experienced metal roofing professionals. A skilled roofing contractor will have the expertise to diagnose the cause of oil canning and implement effective solutions.

Conclusion

Oil canning metal roof is an aesthetic issue that can detract from the overall appearance of your home. While it doesn’t typically affect the structural integrity of the roof, it can be unsightly and a sign of potential underlying problems. Understanding the causes, prevention methods, and repair options is essential for homeowners and contractors alike.

To prevent oil canning, select the right metal gauge, ensure proper installation, use stiffening ribs or striations, and work with a reputable manufacturer. If you’re already experiencing oil canning, consider reinstallation, adding reinforcements, or replacing affected panels.

Proactive measures and working with professionals can preserve your metal roof’s aesthetic and functionality for years.

Leave a Reply