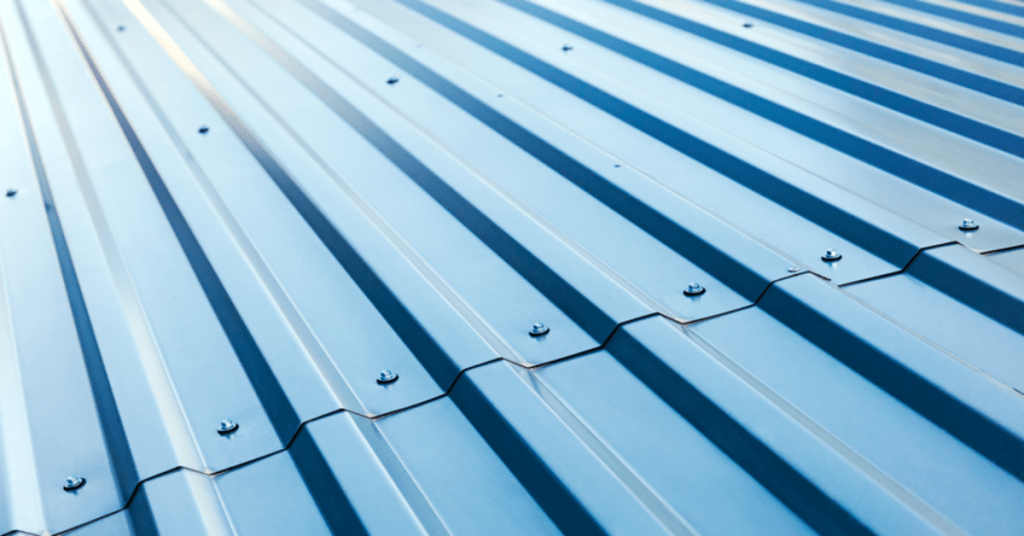

When it comes to installing a metal roof, the screw pattern may not be the first thing that comes to mind, but it plays a crucial role in the performance and longevity of your roofing system. In this article, we’ll delve into the world of screw patterns in metal roofing, exploring why they matter and how they impact the overall integrity of your roof.

The Basics of Screw Patterns:

Securing Your Metal Roof The screw pattern in metal roofing refers to the arrangement and spacing of screws or fasteners used to attach the metal panels to the roof’s substructure. It’s a fundamental aspect of metal roof installation that requires careful consideration.

Factors That Influence Screw Patterns:

Several factors influence the choice of screw patterns in metal roofing:

1. Roof Design: The design of your roof, including its pitch, slope, and complexity, can impact the screw pattern. Roofs with steeper pitches or complex angles may require more fasteners to ensure stability.

2. Wind Zone: The location of your property and its exposure to wind is a critical factor. Homes in high-wind areas typically require more secure screw patterns to prevent wind uplift.

3. Metal Panel Type: Different metal panel types, such as standing seam, corrugated, or ribbed panels, may have specific requirements for screw spacing and placement.

4. Building Codes and Regulations: Local building codes and regulations often dictate the minimum requirements for screw patterns in metal roofing to ensure structural integrity and safety.

Importance of a Proper Screw Pattern:

A Strong Foundation The screw pattern is essential for several reasons:

1. Structural Integrity: A well-designed and correctly executed screw pattern ensures the structural integrity of your metal roof. It prevents panels from shifting, buckling, or lifting during adverse weather conditions.

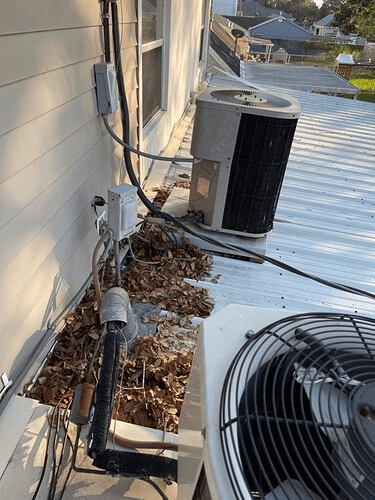

2. Leak Prevention: A proper screw pattern, when combined with appropriate sealants and flashing, helps prevent water infiltration and roof leaks.

3. Wind Resistance: In areas prone to high winds, a secure screw pattern is crucial to prevent wind uplift, which can damage the roof and compromise its performance.

4. Longevity: A carefully planned screw pattern contributes to the longevity of your metal roof. It minimizes the risk of fastener failure, which can lead to premature roof deterioration.

Common Types of Screw Patterns:

Adapted to the Roof’s Needs There are several common screw patterns used in metal roofing:

1. Exposed Fastener Screws: In some metal roofing systems, screws are exposed on the surface of the panels. These screws are strategically placed in a pattern to secure the panels while maintaining the roof’s aesthetics.

2. Hidden Fastener Systems: Concealed fastener systems hide the screws beneath the overlapping panels, providing a sleek and streamlined appearance. The screw pattern in hidden fastener systems is critical for panel alignment and stability.

3. Standing Seam Panels: Standing seam panels have a unique interlocking design that conceals the fasteners. The screw pattern is crucial for securing the seams and preventing water infiltration.

Conclusion:

The screw pattern in metal roofing is far from a mere technical detail; it’s a critical element that ensures the durability, performance, and longevity of your roof. Whether you’re considering a metal roof installation or have an existing metal roof that requires maintenance, understanding and adhering to the appropriate screw pattern is essential for a secure and weather-resistant roofing system.

Leave a Reply