Installing a metal roof requires precise attention to detail, especially when it comes to screw spacing for metal roof panels. Proper screw spacing ensures that the roof is securely fastened, preventing issues such as leaks, wind damage, and panel deformation. This guide will delve into everything you need to know about screw spacing for metal roofs, including why it matters, how to determine the correct spacing, and best practices for installation.

Why Screw Spacing is Crucial for Metal Roofs

Proper screw spacing is critical for several reasons:

1. Structural Integrity

Correct screw spacing ensures that metal roof panels are securely attached to the underlying roof structure. This is crucial for maintaining the roof’s structural integrity and preventing issues such as shifting panels, which can compromise the roof’s performance.

2. Leak Prevention

Properly spaced screws help create a tight seal between the metal panels and the roof deck. This reduces the risk of leaks, which can occur if panels are not secured correctly or if screws are too far apart, allowing for gaps and potential water infiltration.

Read too: How To Replace Roof Shingles That Blew Off: A Comprehensive Guide

3. Wind Resistance

Metal roofs are known for their durability, but improper screw spacing can weaken their resistance to high winds. Adequate screw spacing helps ensure that the panels remain securely fastened, preventing wind uplift and potential damage.

4. Panel Longevity

Proper screw placement reduces the stress and strain on metal panels, which can help extend their lifespan. Panels that are evenly secured are less likely to experience issues such as warping or cracking over time.

How to Determine the Correct Screw Spacing for Metal Roofs

The optimal screw spacing for metal roofs depends on several factors, including the type of metal panels, the roofing system, and local building codes. Here’s a step-by-step guide to help you determine the correct spacing:

1. Check Manufacturer Specifications

The first step in determining the correct screw spacing is to refer to the manufacturer’s specifications for the metal roofing panels you are using. Manufacturers provide detailed installation guidelines, including recommended screw spacing, which should be followed to ensure proper performance and warranty coverage.

2. Consult Local Building Codes

Local building codes may have specific requirements for screw spacing, particularly in areas prone to high winds or extreme weather conditions. It’s important to consult your local building authority to ensure that your installation meets all applicable codes and standards.

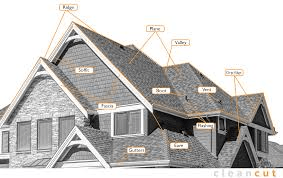

3. Consider Roof Slope and Panel Type

The slope of your roof and the type of metal panels you are using can also impact screw spacing. For example, standing seam metal roofs may require different screw spacing compared to corrugated or ribbed panels. Ensure that you account for these factors when determining the correct spacing.

4. Evaluate Environmental Factors

Environmental conditions, such as wind speed and temperature fluctuations, can affect screw spacing. In regions with high winds, you may need to use closer screw spacing to ensure that the panels remain securely attached. Similarly, temperature changes can cause metal panels to expand and contract, so proper screw spacing helps accommodate these movements.

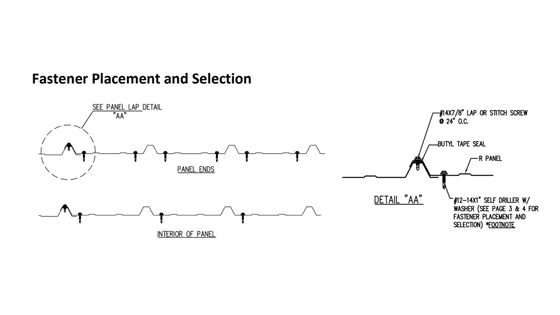

Recommended Screw Spacing for Different Types of Metal Roofs

1. Standing Seam Metal Roofs

Standing seam metal roofs are known for their durability and sleek appearance. The recommended screw spacing for standing seam metal roofs is generally:

- Panel Fasteners: Typically, screws should be placed every 12 to 16 inches along the seam, depending on the panel manufacturer’s recommendations and local building codes.

- Flashing and Trim: Screws for flashing and trim should be placed every 6 to 8 inches to ensure a secure attachment and prevent leaks.

2. Corrugated Metal Roofs

Corrugated metal roofs are commonly used for their rugged appearance and durability. The recommended screw spacing for corrugated metal roofs is typically:

- Panel Fasteners: Screws should be placed every 24 inches along the rib or corrugation. This spacing helps ensure that the panels are securely fastened and provides adequate support.

- Flashing and Trim: For flashing and trim, screws should be placed every 6 to 12 inches to maintain a tight seal and prevent water infiltration.

3. Ribbed Metal Roofs

Ribbed metal roofs, also known as profile or panel roofs, are popular for their strength and ease of installation. The recommended screw spacing for ribbed metal roofs is generally:

- Panel Fasteners: Screws should be placed every 24 to 30 inches along the ribs, depending on the panel type and manufacturer’s guidelines.

- Flashing and Trim: Screws for flashing and trim should be spaced every 6 to 8 inches to ensure proper attachment and prevent leaks.

Best Practices for Installing Metal Roof Screws

To ensure that your metal roof is installed correctly and securely, follow these best practices:

1. Use the Right Screws

Choose screws that are specifically designed for metal roofing. These screws typically have a neoprene washer to create a watertight seal and are made of materials that resist corrosion. Using the wrong type of screw can lead to leaks and premature failure of the roofing system.

2. Pre-Drill Holes if Necessary

For certain types of metal panels, pre-drilling holes may be required to ensure proper screw placement and prevent panel deformation. Follow the manufacturer’s instructions for pre-drilling, if applicable.

3. Ensure Proper Screw Placement

When installing screws, make sure they are placed in the designated areas of the metal panels. Avoid over-tightening, as this can damage the panels and compromise their performance. Screws should be driven straight and perpendicular to the roof surface to ensure a secure attachment.

4. Check Alignment Regularly

During installation, regularly check the alignment of the screws and panels to ensure that they are properly spaced and aligned. This helps prevent issues such as uneven panel placement and ensures that the roof performs as intended.

5. Inspect and Test

After installation, inspect the entire roof to ensure that all screws are properly placed and that there are no gaps or loose panels. Test for leaks by running water over the roof and checking for any signs of water infiltration.

Common Mistakes to Avoid

When it comes to screw spacing for metal roofs, several common mistakes can compromise the integrity of your roofing system. Avoid these pitfalls to ensure a successful installation:

1. Incorrect Screw Spacing

Failing to adhere to the recommended screw spacing can lead to issues such as panel shifting, leaks, and reduced wind resistance. Always follow manufacturer specifications and local building codes for screw spacing.

2. Using Incorrect Fasteners

Using the wrong type of fasteners can result in poor performance and premature failure of the roofing system. Ensure that you use screws that are specifically designed for metal roofing and are compatible with your panel type.

3. Over-Tightening Screws

Over-tightening screws can damage the metal panels and compromise their performance. Tighten screws just enough to create a secure attachment without deforming the panels or compressing the washers excessively.

4. Neglecting Ventilation

Proper ventilation is crucial for the longevity of your metal roof. Ensure that your roof has adequate ventilation to prevent issues such as trapped moisture and heat buildup, which can affect screw performance and panel longevity.

Conclusion: Ensuring Proper Screw Spacing for a Durable Metal Roof

Understanding and implementing the correct screw spacing for metal roof panels is essential for a successful roofing installation. Proper screw placement ensures structural integrity, leak prevention, wind resistance, and extended panel longevity. By following the recommended guidelines, best practices, and avoiding common mistakes, you can achieve a secure and durable metal roof that will protect your home for years to come.

If you have any doubts or questions about screw spacing or metal roof installation, consider consulting a professional roofing contractor. They can provide expert advice and ensure that your metal roof is installed correctly and meets all applicable standards.

Leave a Reply