Proper screw spacing for metal roofing is crucial for ensuring a durable and weather-resistant roof. Whether you’re installing a new metal roof or replacing an existing one, understanding the correct screw spacing will help you avoid common issues such as leaks, sagging, and reduced roof longevity. In this guide, we will delve into the essentials of screw spacing for metal roofing, including why it matters, how to calculate it, and best practices for installation.

Why Screw Spacing Matters for Metal Roofing

Screw spacing for metal roofing is vital for several reasons:

- Structural Integrity: Proper screw placement ensures that the metal panels are securely attached to the underlying structure, which helps maintain the roof’s integrity and prevent movement or shifting.

- Leak Prevention: Incorrect screw spacing can lead to gaps and potential leak points. Ensuring that screws are placed correctly helps seal the panels and prevent water intrusion.

- Load Distribution: Evenly spaced screws distribute the weight of the roof more effectively, reducing stress on individual panels and the overall structure.

- Durability: Proper spacing contributes to the long-term durability of the roof by preventing warping and reducing the risk of panel damage.

Read too: How To Replace Roof Shingles That Blew Off: A Comprehensive Guide

Determining Screw Spacing for Metal Roofing

General Guidelines

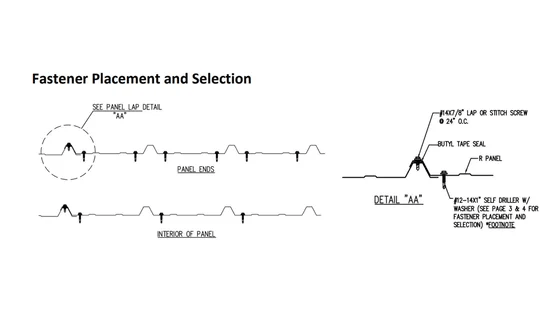

The recommended screw spacing for metal roofing generally follows these guidelines:

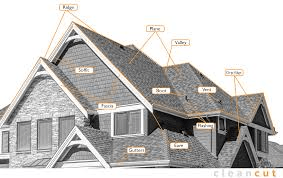

- On the Ridge and Eaves: Screws should be placed every 12 to 24 inches along the metal panel’s length. This spacing ensures a secure attachment without compromising the roof’s functionality.

- In the Field of the Roof: For the field (or middle sections) of the roof, screws are typically spaced 24 inches apart. This spacing provides adequate support while minimizing the risk of panel distortion.

Factors Influencing Screw Spacing

Several factors can influence the optimal screw spacing for your metal roof:

- Panel Type: Different metal roofing panels (e.g., corrugated, standing seam) may have specific spacing requirements. Always refer to the manufacturer’s recommendations.

- Roof Pitch: Steeper roof pitches may require closer screw spacing to ensure panels remain securely fastened.

- Wind Load: Areas prone to high winds may necessitate closer screw spacing to withstand wind forces effectively.

- Climate Conditions: Extreme weather conditions, such as heavy snow or ice, may also affect spacing requirements.

How to Calculate Screw Spacing

Measuring and Marking

- Measure the Roof: Determine the length of each metal panel and the overall roof area.

- Mark the Locations: Using a chalk line or measuring tape, mark the screw locations based on the recommended spacing. Ensure that the marks are aligned to maintain even spacing.

Installation Tips

- Pre-drill Holes: Pre-drilling holes can make installation easier and ensure that screws are placed accurately.

- Use the Right Screws: Use screws specifically designed for metal roofing. These screws typically have a rubber washer that helps seal the hole and prevent leaks.

- Avoid Over-tightening: Tightening screws too much can damage the metal panel or strip the hole. Ensure that screws are snug but not overly tight.

Common Mistakes to Avoid

Incorrect Spacing

- Too Far Apart: Spacing screws too far apart can lead to inadequate support and potential panel movement.

- Too Close Together: Overly close spacing can lead to excessive stress on the panels and potential deformation.

Misalignment

- Off-Center Placement: Ensure screws are placed evenly along the panel to avoid misalignment, which can lead to leaks and other issues.

Using the Wrong Tools

- Inappropriate Fasteners: Using screws that are not designed for metal roofing can lead to issues such as rust and leakage.

Best Practices for Screw Spacing in Metal Roofing

Follow Manufacturer Guidelines

Always refer to the metal roofing manufacturer’s guidelines for specific recommendations on screw spacing. These guidelines are tailored to the panel type and intended use, ensuring optimal performance.

Consider Local Building Codes

Check local building codes and regulations, as they may have specific requirements for screw spacing based on regional climate conditions and structural considerations.

Perform Regular Inspections

Regularly inspect your metal roof to ensure that screws remain secure and that there are no signs of damage or movement. Address any issues promptly to maintain the roof’s effectiveness.

Conclusion

Understanding and implementing the correct screw spacing for metal roofing is crucial for ensuring the durability, functionality, and longevity of your roof. By following the guidelines and best practices outlined in this article, you can effectively manage your metal roofing installation and avoid common issues such as leaks and structural problems. Always refer to manufacturer recommendations and local building codes to ensure that your installation meets all necessary standards.

With proper screw spacing, your metal roof will provide reliable protection and maintain its performance for years to come.

Leave a Reply