When it comes to designing and installing a standing seam metal roof, having accurate CAD (Computer-Aided Design) details is crucial. These details help architects, contractors, and builders ensure that everyf aspect of the roof is correctly designed and executed. This comprehensive guide will cover the essential CAD details for standing seam metal roof, including design considerations, components, and installation practices.

What is a Standing Seam Metal Roof?

Overview of Standing Seam Roofing

A standing seam metal roof is a type of roofing system characterized by its vertical panels with raised seams that interlock to form a continuous, watertight barrier. This design provides a sleek, modern appearance and superior performance. Key features include:

- Vertical Panels: Panels run from the ridge to the eaves, with seams raised above the panel surface.

- Concealed Fasteners: Fasteners are hidden beneath the seams, reducing the risk of leaks and enhancing durability.

- Material Options: Common materials include steel, aluminum, and copper, each offering different benefits in terms of durability and aesthetics.

Read too: How To Replace Roof Shingles That Blew Off: A Comprehensive Guide

Importance of CAD Details for Standing Seam Metal Roofs

Why CAD Details Matter

CAD details play a crucial role in the design and installation of standing seam metal roofs. They provide precise information about the roof’s components, dimensions, and installation methods. Here’s why they are important:

- Accuracy: Ensures that all components fit correctly and meet design specifications.

- Efficiency: Streamlines the construction process by providing clear instructions and reducing the likelihood of errors.

- Compliance: Helps meet building codes and industry standards by detailing the correct installation practices.

Key Components of Standing Seam Metal Roof CAD Details

1. Panel Layout and Dimensions

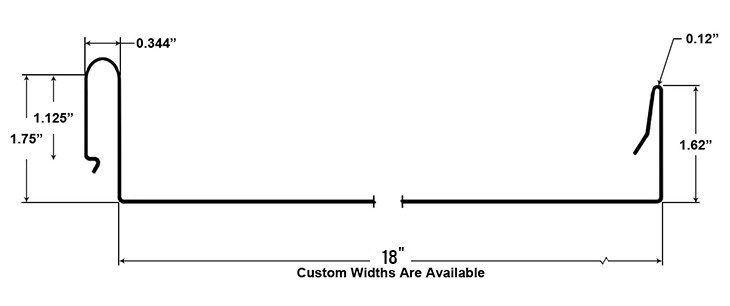

- Panel Sizes: CAD details include the dimensions of each panel, including width, length, and profile height. Accurate measurements are essential for proper installation and ensuring that panels fit together seamlessly.

- Panel Spacing: Details on the spacing between panels and seams help in aligning and securing the panels correctly.

2. Seams and Fasteners

- Seam Design: CAD drawings show the type of seam used (e.g., snap-lock or mechanical seam), including the height and profile of the seams.

- Fastener Locations: Fasteners are hidden under the seams, but CAD details provide information on their placement to ensure proper alignment and stability.

3. Flashing and Trim

- Flashing Details: CAD drawings include the design and placement of flashing, which protects roof penetrations and edges from water infiltration.

- Trim Components: Details on trim pieces, such as ridge caps and eave trims, are included to ensure a complete and finished appearance.

4. Roof Penetrations

- Ventilation and Skylights: CAD details provide information on how to integrate roof penetrations, such as vents and skylights, into the standing seam system.

- Pipe Boots and Seals: Details on how to seal around pipes and other roof penetrations to prevent leaks.

Design Considerations for Standing Seam Metal Roof CAD Details

1. Roof Slope and Drainage

- Slope Requirements: CAD details specify the minimum slope required for proper drainage. Standing seam roofs are typically installed on slopes of at least 3:12 to ensure effective water runoff.

- Drainage Design: Information on how to design the roof to manage water flow, including the placement of gutters and downspouts.

2. Thermal Expansion and Contraction

- Expansion Joints: Details on expansion joints to accommodate the thermal expansion and contraction of metal panels, which helps prevent warping and buckling.

- Allowances: CAD details include allowances for movement to ensure that the roof can expand and contract without causing damage.

3. Structural Support

- Roof Decking: Information on the type of roof decking required to support the standing seam panels and ensure structural integrity.

- Load Calculations: CAD details may include load calculations to ensure that the roof can support additional weight, such as snow or equipment.

Installation Practices and Techniques

1. Preparation and Layout

- Preparation: CAD details outline the preparation steps, including measuring and marking the roof deck for panel placement.

- Layout: Instructions on laying out panels and seams according to the design specifications to ensure proper alignment.

2. Panel Installation

- Installation Sequence: Detailed steps for installing panels, including the order of placement and securing methods.

- Seam Formation: Techniques for forming and securing seams, including the use of hand tools or machinery.

3. Quality Control

- Inspection: Guidelines for inspecting the installation to ensure that all components are correctly aligned and secured.

- Maintenance: Information on routine maintenance practices to keep the roof in optimal condition.

Benefits of Using CAD Details for Standing Seam Metal Roofs

Precision and Efficiency

Using CAD details ensures that the design and installation of a standing seam metal roof are precise and efficient. The detailed drawings reduce the risk of errors and help streamline the construction process.

Compliance and Standards

CAD details help ensure that the roofing system complies with building codes and industry standards, providing a safe and reliable roofing solution.

Enhanced Performance

Accurate CAD details contribute to the overall performance of the roof, including its durability, weather resistance, and aesthetic appeal.

Conclusion

Standing seam metal roofs offer numerous benefits, including durability, aesthetics, and weather resistance. However, achieving these benefits requires precise planning and execution, which is where CAD details come into play. By providing detailed information on panel dimensions, seam design, flashing, and installation practices, CAD details help ensure that your standing seam metal roof performs optimally and meets your design expectations.

Whether you are an architect, contractor, or homeowner, understanding and utilizing CAD details is essential for a successful roofing project. Investing time and effort into accurate design and planning will result in a high-quality, long-lasting roof that enhances the value and functionality of your property.

Leave a Reply