A standing seam metal roof is a popular choice for both residential and commercial buildings due to its durability, longevity, and sleek appearance. However, to ensure the roof’s optimal performance and protection against the elements, paying attention to the standing seam metal roof edge detail is crucial. In this article, we will delve into the significance of the roof edge detail in standing seam metal roofing and why it deserves special consideration during installation and maintenance.

What is Standing Seam Metal Roof Edge Detail?

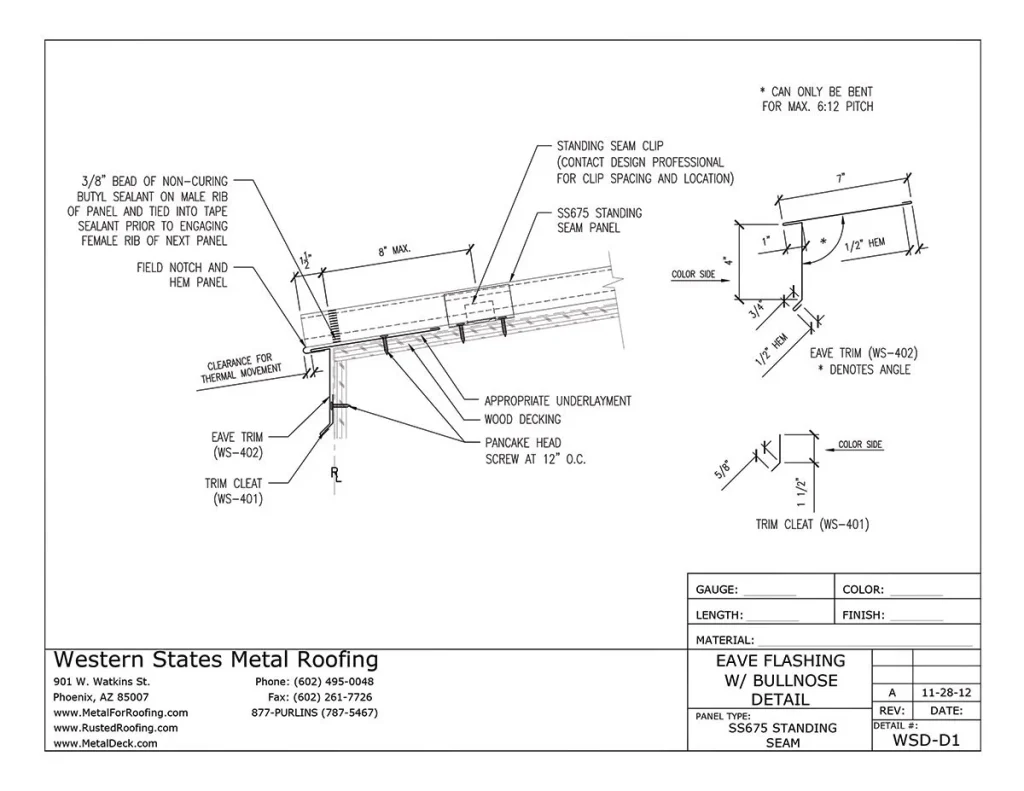

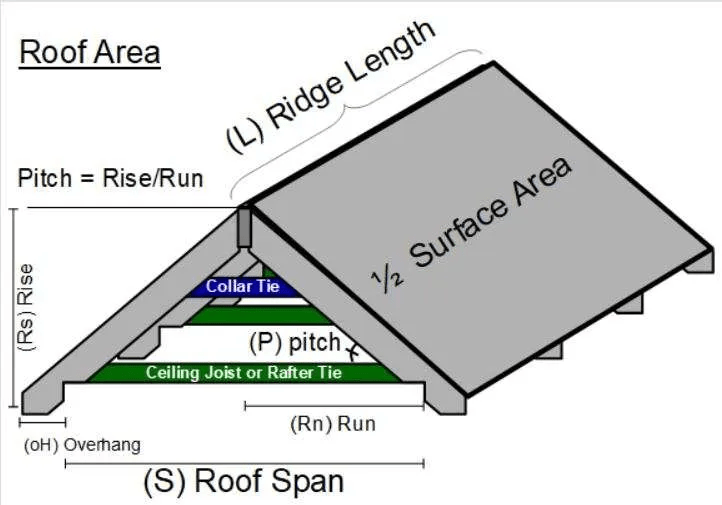

- Defining the Roof Edge Detail: The roof edge detail in a standing seam metal roofing system refers to the area where the roof meets the edge of the building. This includes the eave, gable, and rake edges. Properly executed edge details are essential for preventing water infiltration, wind uplift, and other potential vulnerabilities in the roofing system.

- Components of Edge Detail: The key components of a the roof detail include the fascia, drip edge, and flashing. The fascia is a horizontal band that covers the roof’s edge, providing a smooth appearance and protecting the roof’s perimeter. The drip edge is a metal strip installed along the eaves and gables, directing water away from the underlying structure. Flashing is used to seal joints and transitions, ensuring a watertight and secure roofing system.

Importance

- Water Management: Properly designed edge details are critical for effective water management. The drip edge and flashing work together to direct rainwater and melting snow away from the roof’s edge and prevent it from seeping into the building. This helps protect the roof’s structural integrity and prevents water damage to the interior of the property.

- Wind Uplift Resistance: The roof edge detail plays a crucial role in the wind uplift resistance of a standing seam metal roof. Securely anchored edge details prevent the metal panels from lifting during strong winds, ensuring the roof remains intact even in severe weather conditions.

Considerations During Installation

- Expertise and Experience: Proper installation of the roof details requires expertise and experience. Hiring a professional roofing contractor with a proven track record in metal roofing installations is essential to ensure the edge details are executed correctly.

- Quality Materials: Using high-quality materials for the edge detail, such as corrosion-resistant flashing and sturdy drip edges, is essential for the long-term performance of the roofing system.

- Adherence to Manufacturer Guidelines: Following the manufacturer’s guidelines and specifications during installation is crucial to ensure the standing seam metal roof edge detail meets industry standards and warranty requirements.

Maintenance and Inspection

Regular maintenance and inspections are necessary to keep the roof detail in optimal condition. Here are some maintenance tips:

- Cleaning and Clearing Debris: Regularly clean the roof and remove debris, such as leaves and branches, from the roof edge and gutters. Clogged gutters can cause water to back up and compromise the edge detail’s functionality.

- Inspection for Damage: Conduct routine inspections to check for any signs of damage, such as loose flashing or damaged drip edges. Promptly address any issues to prevent further damage and maintain the roof’s performance.

Conclusion

In conclusion, the standing seam metal roof edge detail is a critical component of a durable and high-performing roofing system. Properly designed and installed edge details ensure effective water management, wind uplift resistance, and long-term protection for the building. When installing this roof, it is essential to work with experienced roofing professionals who understand the intricacies of edge detail installation. Regular maintenance and inspections further contribute to the roof’s longevity and reliability, ensuring it continues to safeguard the property for many years to come.

Leave a Reply