When installing metal roofing, understanding the correct overlapping technique is crucial for ensuring a durable and watertight roof. Many homeowners and contractors may wonder, “Which side of metal roofing overlaps?” This seemingly simple question has significant implications for the performance and longevity of the roofing system. In this comprehensive guide, we will explore the principles of metal roofing overlap, best practices for installation, and the factors that influence overlap orientation.

Understanding Metal Roofing Overlap

Metal roofing panels are designed to overlap each other to provide a secure and weather-resistant roof. Overlapping helps to prevent water infiltration, wind uplift, and other issues that could compromise the roof’s integrity. Proper overlap is essential to achieving a long-lasting and effective metal roof.

The Purpose of Overlapping

- Waterproofing: The primary purpose of overlapping is to ensure that water flows over the seams rather than penetrating them. Proper overlap prevents leaks and keeps the interior of the building dry.

- Wind Resistance: Overlapping also helps to secure the panels against strong winds, reducing the risk of panels being lifted or displaced.

- Structural Integrity: Overlapping adds to the structural strength of the roofing system by distributing stresses and loads more evenly across the panels.

Read too: How To Replace Roof Shingles That Blew Off: A Comprehensive Guide

Which Side of Metal Roofing Overlaps?

Standard Overlap Techniques

In metal roofing installation, the overlap direction typically follows these guidelines:

- Downward Overlap: The general rule is that the upper panel should overlap the lower panel. This technique ensures that water flows over the seam rather than under it. The upper panel’s edge should extend over the edge of the lower panel to direct water away from the seam.

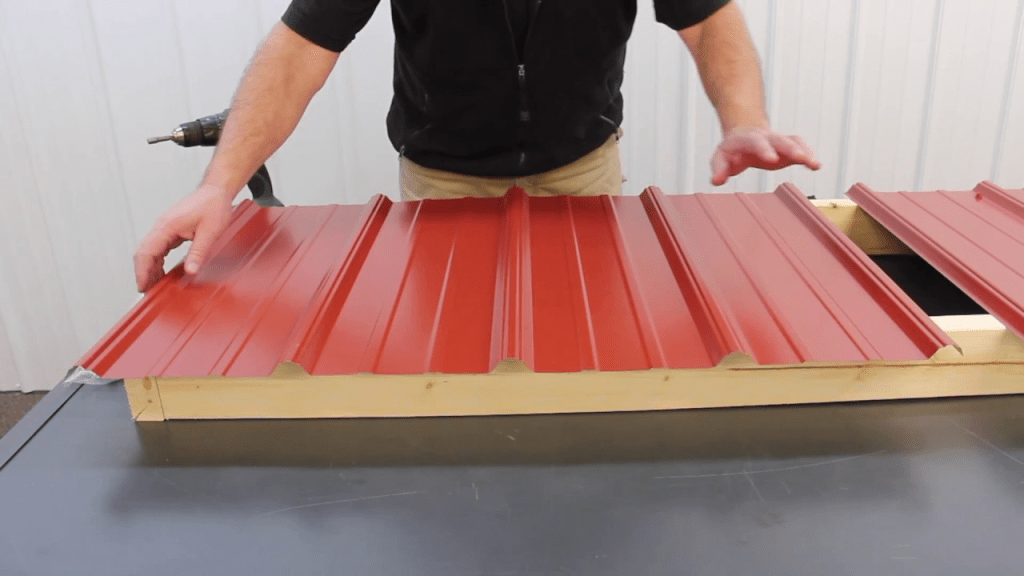

- Side Overlap: When it comes to side laps (where panels meet side by side), the side with the “male” edge should overlap the “female” edge of the adjacent panel. This setup allows for a watertight seal and prevents water from entering through the seams.

Orientation of Overlap

- Ridge Cap Overlap: When installing the ridge cap (the panel that runs along the top of the roof), it should overlap the panels below. This is done to ensure that water flows away from the ridge and does not seep into the roof system.

- End Laps: For end laps (where one panel ends and another begins), the end of the upper panel should overlap the beginning of the lower panel. This configuration directs water away from the seam.

Best Practices for Metal Roofing Overlap

1. Follow Manufacturer Guidelines

Each metal roofing manufacturer may have specific guidelines for overlapping their products. Always refer to the manufacturer’s installation instructions for precise recommendations on overlap orientation and dimensions.

2. Ensure Proper Panel Alignment

Accurate panel alignment is crucial for effective overlap. Misaligned panels can lead to gaps and leaks. Use chalk lines or other alignment tools to ensure that panels are correctly positioned before fastening.

3. Use Quality Fasteners

High-quality fasteners are essential for securing the panels and maintaining the overlap. Choose fasteners that are compatible with your metal roofing material and ensure they are properly installed to avoid leaks.

4. Avoid Over-tightening

While it is important to secure the panels firmly, avoid over-tightening the fasteners. Over-tightening can deform the metal panels and compromise the overlap. Follow the manufacturer’s recommendations for the correct fastening torque.

5. Seal Overlaps Properly

In addition to overlapping, it is often recommended to use sealants or roofing tapes to seal the seams. This extra step helps to prevent water infiltration and enhances the overall waterproofing of the roof.

Factors Influencing Metal Roofing Overlap

1. Roof Pitch

The pitch of the roof (the angle of the roof slope) can affect the overlap requirements. Steeper pitches may require more overlap to ensure proper water runoff, while flatter roofs may need additional sealing.

2. Climate

The local climate plays a role in determining the appropriate overlap. In areas with heavy rainfall or snow, more substantial overlaps and additional sealing may be necessary to prevent leaks.

3. Panel Type

Different types of metal panels (e.g., standing seam, corrugated) may have varying overlap requirements. Ensure you are following the correct practices for the specific panel type you are using.

4. Roof Design

Complex roof designs with multiple angles, valleys, or hips may require special attention to overlap and sealing. Consult with a professional roofer to address these complexities effectively.

Common Mistakes to Avoid

1. Inadequate Overlap

Not providing sufficient overlap can lead to water infiltration and roof damage. Ensure that the overlap meets or exceeds the manufacturer’s recommendations.

2. Misalignment

Misaligned panels can cause gaps and compromise the effectiveness of the overlap. Take time to align panels carefully before fastening.

3. Ignoring Manufacturer Instructions

Ignoring the manufacturer’s installation instructions can result in improper overlap and potential issues. Always follow the guidelines provided by the metal roofing manufacturer.

Conclusion

Understanding which side of metal roofing overlaps is crucial for achieving a durable and watertight roof. By following proper overlap techniques, aligning panels accurately, and using quality materials, you can ensure that your metal roofing system performs effectively and stands the test of time. Whether you are a homeowner or a contractor, paying attention to these details will help you achieve a high-quality metal roof that provides long-lasting protection and value.

Leave a Reply