When installing a metal roof, the spacing of purlins plays a crucial role in ensuring structural integrity and longevity. Among the various options available, the 2X4 purlin spacing is a popular choice. This guide will provide you with detailed insights into the optimal spacing for 2X4 purlin on a metal roof, helping you achieve a robust and durable roofing system.

Understanding Purlins and Their Role

What Are Purlins?

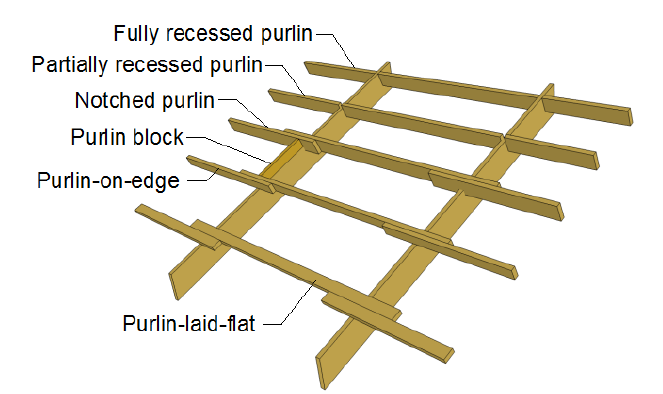

Purlins are horizontal structural members used to support the roofing material and distribute its weight across the rafters or trusses. They are critical in providing the framework for attaching roof panels, especially for metal roofing systems. Purlins help ensure that the roof remains stable under various weather conditions and maintains its shape over time.

Types of Purlins

- C-Channel Purlins: Shaped like a “C”, these are commonly used due to their strength and versatility.

- Z-Channel Purlins: Shaped like a “Z”, they offer additional support and can be used in combination with C-channel purlins.

- 2X4 Purlins: Typically made from wood, these purlins are used in residential and light commercial applications.

Read too: How To Replace Roof Shingles That Blew Off: A Comprehensive Guide

Why Is Spacing Important?

Impact on Structural Integrity

Proper spacing of purlins is essential to ensure that the metal roof panels are adequately supported. Incorrect spacing can lead to sagging, warping, or even failure of the roofing system. Adequate spacing distributes the load evenly and prevents stress points that could lead to premature wear or damage.

Influence on Roof Performance

The spacing of purlins affects the roof’s overall performance, including its ability to withstand wind loads, snow loads, and other environmental factors. Properly spaced purlins help maintain the roof’s shape and prevent leaks or other issues.

Optimal 2X4 Purlin Spacing for Metal Roof

General Guidelines

The spacing of 2X4 purlins for metal roofs typically ranges from 24 inches to 36 inches on center. However, the exact spacing may vary based on factors such as:

- Roof Pitch: Steeper pitches often require closer purlin spacing to provide additional support.

- Metal Roof Panel Type: Different types of metal panels may have specific requirements for purlin spacing.

- Local Building Codes: Always refer to local building codes and manufacturer recommendations for specific guidelines.

Factors Affecting Spacing

1. Load-Bearing Capacity

The load-bearing capacity of 2X4 purlins depends on their grade, species, and moisture content. Heavier roofs or those subjected to significant environmental loads may require closer spacing to ensure adequate support.

2. Roof Design and Pitch

A roof with a lower pitch or a complex design may require closer purlin spacing to maintain structural integrity and prevent issues like sagging or uneven weight distribution.

3. Climate and Weather Conditions

In areas with heavy snowfall or high winds, closer purlin spacing is essential to provide additional support and prevent damage. Conversely, in mild climates, wider spacing may be acceptable.

Recommended Spacing for Various Scenarios

- Residential Roofs: For typical residential applications, 24 inches to 30 inches on center is often sufficient for 2X4 purlins.

- Commercial Roofs: Light commercial applications may require closer spacing, such as 24 inches on center, to accommodate higher loads.

- Heavy Loads: In areas with heavy snow or wind loads, consider reducing the spacing to 24 inches or even closer, depending on the specific requirements.

Installing 2X4 Purlins for Metal Roof

Preparation and Tools

Before installation, ensure you have the necessary tools and materials, including:

- 2X4 Purlins

- Metal Roof Panels

- Measuring Tape

- Level

- Drill and Screws

- Safety Gear

Installation Steps

- Measure and Mark: Determine the required spacing for your purlins and mark the positions on the roof framing.

- Cut Purlins: Cut the 2X4 purlins to the desired length, ensuring they fit the marked positions.

- Install Purlins: Secure the purlins to the roof framing using appropriate fasteners. Ensure they are level and evenly spaced according to the guidelines.

- Attach Metal Panels: Once the purlins are installed, attach the metal roof panels, ensuring they align with the purlins and are properly secured.

Quality Control and Inspection

After installation, inspect the purlins and roof panels to ensure everything is properly aligned and securely fastened. Check for any signs of misalignment or gaps that could lead to issues.

Maintenance and Longevity

Regular Inspections

Regularly inspect your metal roof and purlins for signs of wear, damage, or shifting. Address any issues promptly to prevent more significant problems and maintain the roof’s performance.

Cleaning and Care

Keep the roof and purlins clean and free of debris to prevent blockages and potential damage. Ensure that gutters and downspouts are clear to allow proper drainage.

Conclusion

Understanding and implementing the correct 2X4 purlin spacing for your metal roof is crucial for ensuring a durable and reliable roofing system. By considering factors such as load-bearing capacity, roof design, and local building codes, you can achieve optimal performance and longevity for your metal roof. Proper installation and regular maintenance will help keep your roof in excellent condition, providing protection and peace of mind for years to come.

Leave a Reply