Metal roofing is known for its durability, longevity, and exceptional performance in a variety of weather conditions. One critical aspect of installing a metal roof is understanding the concept of overlap length. The overlap length, or how much one metal roofing panel overlaps another, is a crucial factor in ensuring the roof’s watertight integrity and overall structural integrity. In this article, we will explore the importance of metal roof overlap length, how it is determined, and its significance in a successful metal roofing installation.

The Significance of Metal Roof Overlap Length

1. Waterproofing and Weather Resistance

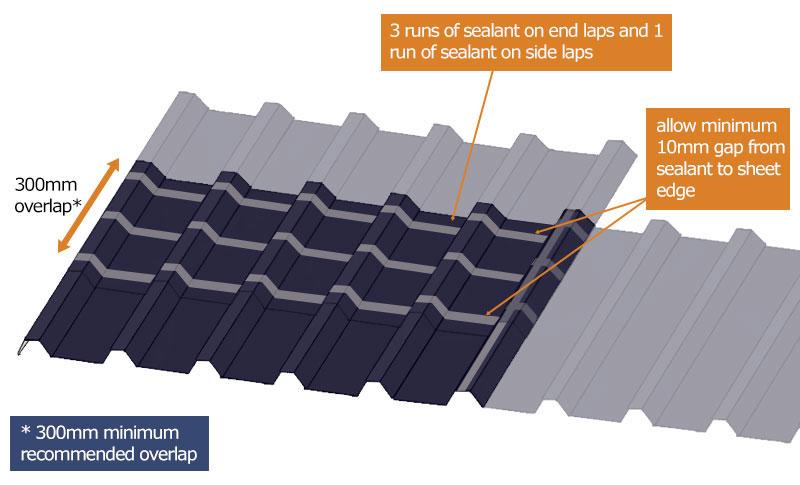

The primary purpose of the overlap length in metal roofing is to create a barrier against water infiltration. This is especially critical in regions prone to heavy rain, snow, or other forms of precipitation. When metal roofing panels overlap correctly, they prevent water from seeping beneath the panels and into the building structure.

2. Structural Integrity

The overlap length also contributes to the structural integrity of the metal roof. Proper overlap ensures that the roofing system can withstand various forces, including wind uplift, snow loads, and thermal expansion and contraction.

Determining the Correct Metal Roof Overlap Length

1. Manufacturer Guidelines*

Metal roofing manufacturers typically provide guidelines for the recommended overlap length for their specific products. These guidelines are based on extensive testing and engineering to ensure the roofing panels perform as intended.

2. Local Building Codes*

Local building codes and regulations may specify the minimum required overlap length for metal roofing installations. It is essential to comply with these codes to ensure the safety and legality of your roofing project.

Factors Affecting Metal Roof Overlap Length

Several factors influence the determination of the appropriate overlap length for a metal roofing project:

1. Roof Pitch*

The pitch or slope of the roof affects the required overlap. Steeper roofs may require a larger overlap to prevent water from infiltrating against gravity.

2. Roof Design*

Complex roof designs, such as those with multiple valleys, dormers, or skylights, may require specific overlap lengths in different areas to ensure proper water drainage and weather resistance.

3. Local Climate*

The climate of the region where the metal roof is installed is a significant factor. Areas with heavy rainfall, snow, or high winds may require larger overlap lengths to withstand the weather.

Installation Tips

When installing a metal roof, here are some essential tips regarding overlap length:

1. Follow Manufacturer Recommendations*

Always adhere to the manufacturer’s recommended overlap length for the specific metal roofing product you are using. Deviating from these guidelines can compromise the roof’s performance.

2. Use High-Quality Fasteners*

Properly fasten the roofing panels with high-quality screws or fasteners designed for metal roofing. Ensure they are correctly installed to prevent leaks.

3. Pay Attention to Seams*

Take extra care when overlapping panels at seams and joints. Properly seal and flash these areas to prevent water intrusion.

Conclusion

The metal roof overlap length is a critical element in ensuring the longevity and performance of a metal roofing system. It plays a vital role in preventing water infiltration, maintaining structural integrity, and withstanding various environmental forces. To ensure a successful metal roofing installation, it is essential to follow manufacturer guidelines, adhere to local building codes, and consider the specific factors that may affect the required overlap length for your project.

Leave a Reply