In the realm of modern roofing, standing seam metal roofs have gained immense popularity due to their durability, energy efficiency, and sleek appearance. To bring these remarkable roofs to life, precision in design and construction is paramount. This is where Standing Seam Metal Roof Details CAD (Computer-Aided Design) comes into play, offering a powerful tool to architects, engineers, and roofing professionals. Let’s delve into the world of standing seam metal roofs and explore how CAD technology revolutionizes the way we design and execute roofing projects.

Understanding the Standing Seam Metal Roof Concept:

What Is a Standing Seam Metal Roof? A standing seam metal roof is a type of roofing system characterized by its vertical metal panels with raised seams or ribs. These panels interlock vertically along the roof’s surface, creating a continuous, sleek appearance. Renowned for its durability, weather resistance, and modern aesthetic, this roofing style stands out.

Benefits of Standing Seam Metal Roofs:

- Durability: Standing seam roofs are built to last, often outliving traditional roofing materials like asphalt shingles.

- Energy Efficiency: Their reflective surfaces can help reduce cooling costs, making them an environmentally friendly choice.

- Low Maintenance: Minimal maintenance is required, saving homeowners time and money.

- Aesthetic Appeal: The clean lines and modern look enhance a building’s curb appeal.

The Role of CAD in Standing Seam Metal Roof Design:

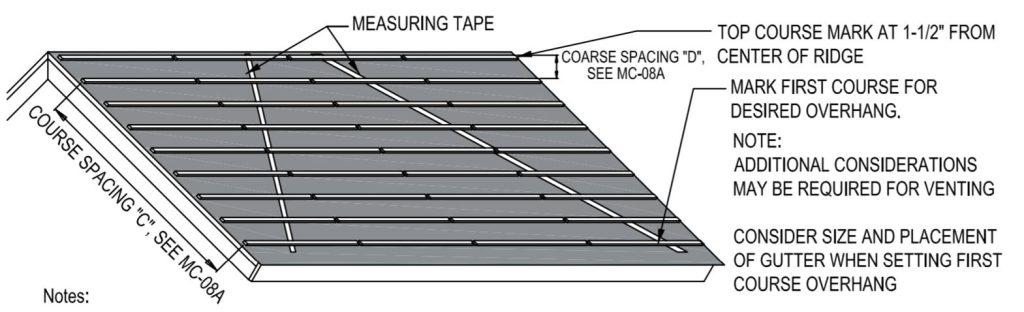

Precise Measurements and Layouts CAD technology allows for precise measurements and layouts of standing seam metal roofs. Designers can create accurate 2D and 3D models, ensuring that every panel, seam, and attachment point is in the right place. This precision is crucial for preventing leaks and ensuring the roof’s longevity.

Material Selection and Estimation CAD software provides tools for material selection and estimation. Designers can input material specifications and get accurate quantity and cost estimations, helping project planners stay within budget.

Visualization and Collaboration CAD allows stakeholders to visualize the finished product before construction begins. This aids in decision-making and streamlines the design process. Additionally, CAD facilitates collaboration between architects, engineers, and contractors, ensuring everyone is on the same page.

Implementing Standing Seam Metal Roof Details CAD:

Step 1: Site Assessment

Before using CAD, a thorough site assessment is essential. Factors like climate, local building codes, and roof pitch must be considered to create an appropriate design.

Step 2: CAD Modeling

Once the site assessment is complete, CAD software is used to create a detailed model of the standing seam metal roof. This model includes panel placement, seam types, attachment points, and structural support.

Step 3: Material Selection

CAD software assists in selecting the right materials, including the type of metal, finish, and insulation. The software calculates material quantities and generates a cost estimate.

Step 4: Review and Approval

The CAD model is reviewed by the project team and, if necessary, modified to address any concerns. Once approved, the design becomes the blueprint for construction.

Conclusion:

Standing seam metal roofs offer numerous benefits, making them a preferred choice for many modern construction projects. When it comes to designing and executing these roofs, Standing Seam Metal Roof Details CAD plays a pivotal role. It ensures precision, cost-effectiveness, and collaboration among project stakeholders, ultimately leading to the creation of durable, efficient, and aesthetically pleasing roofing systems.

Leave a Reply