When it comes to metal roofing, one of the critical factors in ensuring a weather-tight and long-lasting installation is the minimum overlap. Properly overlapping metal roofing panels is crucial for preventing leaks, enhancing durability, and ensuring the roof performs well under various weather conditions. This article explores the importance of minimum overlap for metal roofing, provides detailed guidelines, and offers practical tips for achieving a successful installation.

What is Minimum Overlap for Metal Roofing?

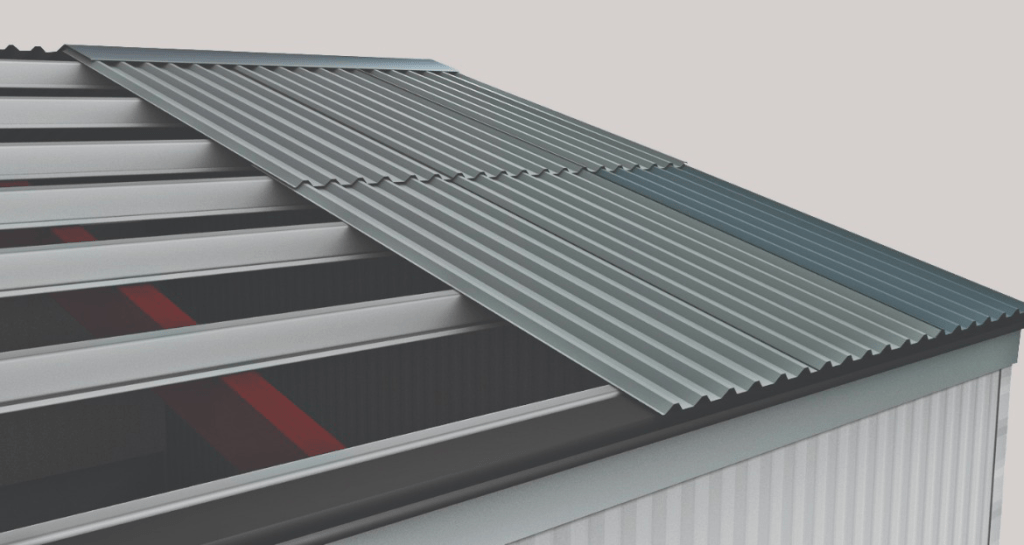

Minimum overlap for metal roofing refers to the amount by which one metal panel should extend over the adjacent panel to ensure that water and debris do not penetrate between them. Overlap is a key aspect of metal roofing installation, as it plays a vital role in maintaining the integrity and effectiveness of the roofing system.

Why is Minimum Overlap Important?

- Waterproofing: The primary purpose of overlap is to create a waterproof barrier. Proper overlap prevents water from seeping between panels, reducing the risk of leaks and water damage.

- Durability: Adequate overlap helps in distributing the weight and stress across the roof, enhancing the overall durability and longevity of the roofing system.

- Weather Resistance: Overlap provides additional protection against extreme weather conditions, including heavy rain, snow, and high winds.

- Aesthetic Consistency: Consistent overlap ensures a neat and uniform appearance of the roof, contributing to the overall aesthetic appeal of the building.

Read too: How To Replace Roof Shingles That Blew Off: A Comprehensive Guide

How to Determine the Minimum Overlap for Metal Roofing

1. Consult Manufacturer Guidelines

Different types of metal roofing materials and systems have varying requirements for overlap. Always consult the manufacturer’s guidelines or installation instructions for specific recommendations on minimum overlap. These guidelines are designed to ensure optimal performance and compliance with industry standards.

2. Consider Roofing Panel Type

The type of metal roofing panel you choose can affect the minimum overlap required. Common types of metal roofing panels include:

- Standing Seam Panels: Typically, standing seam panels require an overlap of 1.5 to 2 inches. This type of panel features raised seams that interlock, providing a secure and waterproof connection.

- Ribbed Panels: Ribbed or corrugated panels often need a minimum overlap of 2 to 3 inches. The overlapping ribs help channel water away from the roof surface and prevent leaks.

- Metal Shingles: For metal shingles, overlap requirements can vary based on the design and manufacturer specifications. Generally, metal shingles overlap by 1 to 2 inches.

3. Account for Roof Pitch and Slope

The pitch and slope of your roof can impact the overlap requirements. Steeper roofs may require less overlap due to the increased slope facilitating water runoff, while flatter roofs may need more overlap to ensure proper water drainage. Consult local building codes and guidelines to determine the appropriate overlap for your roof’s pitch.

4. Local Climate and Weather Conditions

Consider the local climate and weather conditions when determining the overlap. Areas prone to heavy rain, snow, or high winds may require additional overlap to enhance weather resistance. Discuss with roofing professionals to assess the specific needs of your region.

How to Install Metal Roofing with Proper Overlap

1. Preparation and Safety

- Gather Materials and Tools: Ensure you have all the necessary materials, including metal roofing panels, fasteners, underlayment, and safety gear such as harnesses and gloves.

- Safety First: Use appropriate safety measures when working on the roof, including fall protection and proper ladder use.

2. Install the Underlayment

- Apply Underlayment: Before installing metal roofing panels, lay down a suitable underlayment to provide an additional layer of protection against moisture and improve insulation.

- Overlap Underlayment: Overlap the underlayment by at least 2 to 3 inches to ensure a continuous barrier beneath the metal panels.

3. Install the First Row of Metal Panels

- Position Panels: Start by positioning the first row of metal panels at the eaves of the roof. Ensure that the panels are aligned properly and that the bottom edge extends slightly beyond the eaves.

- Secure the Panels: Use appropriate fasteners to secure the panels to the roof deck. Follow the manufacturer’s recommendations for fastener spacing and installation techniques.

4. Overlap Subsequent Rows

- Align Panels: For each subsequent row, position the panels so that they overlap the previous row by the specified minimum amount. Ensure that the overlap covers the fasteners of the row below to prevent leaks.

- Fasten Panels: Secure the overlapping panels with fasteners, making sure to follow the recommended spacing and installation guidelines.

5. Seal Overlaps and Edges

- Apply Sealant: Use roofing sealant or silicone to seal the overlaps and edges of the metal panels. This additional step helps to enhance the waterproofing and prevent water infiltration.

- Check for Gaps: Inspect the entire roof to ensure that there are no gaps or areas where the overlap is insufficient.

Tips for a Successful Metal Roofing Installation

- Follow Manufacturer Instructions: Always adhere to the manufacturer’s instructions for both overlap and installation techniques to ensure warranty compliance and optimal performance.

- Use Quality Materials: Invest in high-quality metal roofing panels and fasteners to ensure durability and long-term reliability.

- Maintain Consistency: Ensure consistent overlap throughout the entire roof to avoid weak spots and potential leaks.

- Professional Assistance: If you are unsure about the overlap requirements or installation process, consider consulting with a professional roofer to ensure a proper and effective installation.

Common Mistakes to Avoid

- Inadequate Overlap: Insufficient overlap can lead to leaks and water damage. Always ensure that the overlap meets or exceeds the minimum recommended by the manufacturer.

- Improper Fastening: Incorrectly spaced or insufficiently driven fasteners can compromise the integrity of the roof. Follow the manufacturer’s guidelines for fastener placement.

- Neglecting Sealing: Failing to seal overlaps and edges can result in water infiltration. Use appropriate sealants to enhance the waterproofing of the roof.

Conclusion

Understanding and implementing the correct minimum overlap for metal roofing is essential for ensuring a durable and weather-resistant roofing system. By following manufacturer guidelines, considering roof type and pitch, and using proper installation techniques, you can achieve a successful metal roofing installation that provides long-lasting protection for your home or building. Whether you are a DIY enthusiast or a professional roofer, paying attention to the details of overlap will contribute to the overall quality and effectiveness of your roofing project.

Leave a Reply